Zimmermann and you

Machining solutions and you.

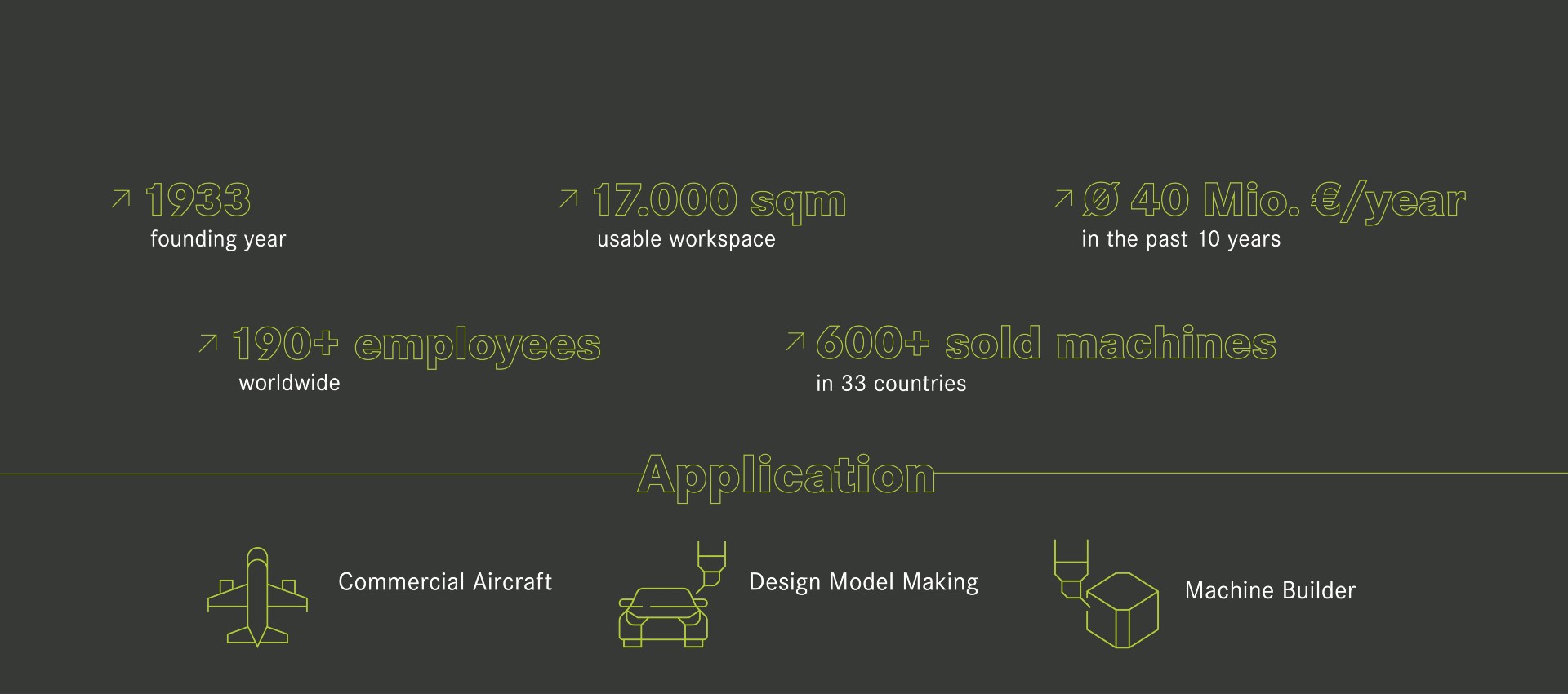

Welcome to F. Zimmermann GmbH – your reliable partner for innovative milling solutions for over 90 years. As a family-run company, we focus on people. Our customers, employees and suppliers are in the center of our activities. It is particularly important to us to build long-term partnerships and maintain close cooperation. Since our foundation, we have continuously developed and are proud to be the technological leader in our industry. Our modular machine system allows freedom for design. The innovative thermo-symmetrical gantry ensures the highest accuracy. Together with you we develop your milling machine with passion and precision. This is how we find the right solution for every requirement, industry, component, material or surface!

Management Team

Frieder Gänzle

President CEO

Eva Gänzle

Head of Commercial Department

In-house Lawyer

US subsidiary

Zimmermann Inc.

Founded: 2005 | Location: Wixom, MI, USA | Assembly area: ca. 1.000 m² | Employees: 13

President: Cornelius Kiesel

Services

- Sales

- Assembly operations

- Service/After Sales

- Application engineering support

- Show room and spare parts warehouse

Our history

Establishment

Friedrich Zimmermann establishes the company as a contract manufacturer

and service provider for electrical installations.

Acquisition

Rudolf Gänzle takes over 100% of the business shares. Zimmermann develops into a niche supplier for portal milling machines.

Expansion

Zimmermann expands at the Denkendorf site and opens up the markets of China and North America

New building

New construction of the company building at the current headquarters in Neuhausen a.d.F.

USA

Construction of the new headquarters of the subsidiary Zimmermann Inc. with showroom on approx. 1.300 m² at the location Wixom, Michigan.

Extension

New building and inauguration of the Competence Center Technology on approx. 4.500m² floor space

Next Generation

Frieder Gänzle takes over the management of the company and Eva Gänzle then joins the commercial management.

Innovation

Market launch of the thermosymmetrical "modular plant system" (MAB)

Lightweight

Acquisition of EiMa Maschinenbau GmbH. Expansion of the portal milling machine portfolio to include a lightweight segment.

Certificates and guidelines

Reliability is not only part of our DNA, but also of our processes. Thus, we continuously strive to improve ourselves in order to meet the quality demands placed on us. To achieve this, we regularly have ourselves certified by independent audits. Integrity, fairness and partnership are integral to our understanding of value-based action. We also want to live up to our social responsibility by voluntarily imposing environmental standards. Sustainable action is part of our corporate culture and products.