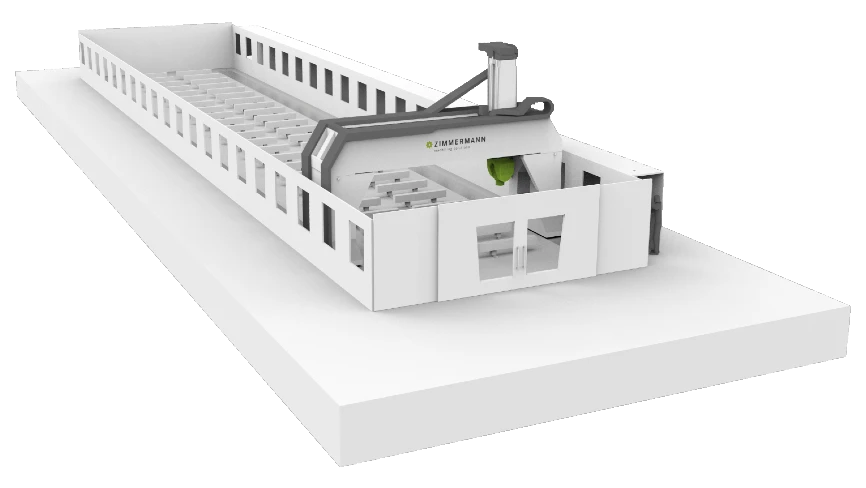

M3ABC

Milling Head M3ABC

Powerful. Flexible. Efficient.

The dynamic 3-axis milling head M3ABC (A, B and C axis) sets new standards in volume cutting of aluminium, composite and model construction materials as well as in HSC machining of steel and cast iron. Where conventional 2-axis milling heads reach their performance limits, the M3ABC allows different workpieces to be machined four times faster.

The fork head is designed in monobloc design made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping for maximum surface quality and cutting performance. The M3ABC is fully flexible and has been specially developed for machining structural parts. Maximum cutting volume, short throughput times and high cost-effectiveness are the hallmarks of this machine.

Technical Data

stdClass Object ( [id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [machine_id] => 258557 [category] => FZP42 & FZU42 [attributes] => Array ( [0] => stdClass Object ( [id] => a2ceb29a-d54f-4508-b1f0-7827ae3f84f9 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Milling Head [values] => Array ( [0] => stdClass Object ( [id] => 57678593-16f7-48b7-8173-fcd0479e075d [attribute_id] => a2ceb29a-d54f-4508-b1f0-7827ae3f84f9 [value] => [subvalues] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 637e6462-e704-441b-aa62-2da33ce47681 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Torque Rotary Axes [values] => Array ( [0] => stdClass Object ( [id] => 5e52f4a4-d122-4ca3-a916-6230cc689dbe [attribute_id] => 637e6462-e704-441b-aa62-2da33ce47681 [value] => in control [subvalues] => Array ( [0] => stdClass Object ( [id] => 538e3899-0339-4ec2-b1f6-a9bc9fe17fa2 [value_id] => 5e52f4a4-d122-4ca3-a916-6230cc689dbe [subvalue] => A-Axis: 1.200 Nm (885 ft lb) [subvalues2] => Array ( ) ) [1] => stdClass Object ( [id] => 18d23a88-b7f2-4ac5-8bdd-3b9fa3901f8f [value_id] => 5e52f4a4-d122-4ca3-a916-6230cc689dbe [subvalue] => C-Axis: 1.047 Nm (772 ft lb) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => c8080bc6-57a4-4783-ab07-ad5bdf9abefa [attribute_id] => 637e6462-e704-441b-aa62-2da33ce47681 [value] => clamped [subvalues] => Array ( [0] => stdClass Object ( [id] => 5f696cc7-129e-47a8-832e-abeb5a46ea0d [value_id] => c8080bc6-57a4-4783-ab07-ad5bdf9abefa [subvalue] => A-, C-Axis: 3.000 Nm (2212 ft lb) [subvalues2] => Array ( ) ) ) ) ) ) [2] => stdClass Object ( [id] => 984f5a69-b41f-4945-a7bf-37515c30c575 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Swiveling Range [values] => Array ( [0] => stdClass Object ( [id] => f84ea064-4a79-4ef4-8b44-d3727e279290 [attribute_id] => 984f5a69-b41f-4945-a7bf-37515c30c575 [value] => [subvalues] => Array ( ) ) ) ) [3] => stdClass Object ( [id] => 2475631f-ee73-4815-86a5-78192fe5ad9a [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => A-Axis [values] => Array ( [0] => stdClass Object ( [id] => b47f3361-b58b-4f36-a922-e53769407e6f [attribute_id] => 2475631f-ee73-4815-86a5-78192fe5ad9a [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => dd2d9193-223d-4875-853f-8d820581354c [value_id] => b47f3361-b58b-4f36-a922-e53769407e6f [subvalue] => ± 110° oder +125/-95° [subvalues2] => Array ( ) ) ) ) ) ) [4] => stdClass Object ( [id] => cf72f093-9c80-4f3a-801d-8e7447f80fd4 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => C-Axis [values] => Array ( [0] => stdClass Object ( [id] => 6e954ef3-c32a-4e61-8675-d39cfc5f9da0 [attribute_id] => cf72f093-9c80-4f3a-801d-8e7447f80fd4 [value] => Z-Axis < 1.500 mm (59") [subvalues] => Array ( [0] => stdClass Object ( [id] => eb739276-1abb-4308-be8d-7f960e5fd657 [value_id] => 6e954ef3-c32a-4e61-8675-d39cfc5f9da0 [subvalue] => 300° [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 9bb94f5d-d253-467c-ae19-ddbe093a7867 [attribute_id] => cf72f093-9c80-4f3a-801d-8e7447f80fd4 [value] => Z-Axis ≥ 1.500 mm (59") [subvalues] => Array ( [0] => stdClass Object ( [id] => ee77ba33-cfae-47b5-8cf6-129dce6aecbd [value_id] => 9bb94f5d-d253-467c-ae19-ddbe093a7867 [subvalue] => 360° [subvalues2] => Array ( ) ) ) ) ) ) [5] => stdClass Object ( [id] => 5a38d7f7-d746-434d-a89b-662d5d17e9ea [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Drives - Rotary Axes [values] => Array ( [0] => stdClass Object ( [id] => eb916d17-ee72-46a5-b628-c9bd09589278 [attribute_id] => 5a38d7f7-d746-434d-a89b-662d5d17e9ea [value] => [subvalues] => Array ( ) ) ) ) [6] => stdClass Object ( [id] => 86093243-873c-498f-badd-568cc3bcd9ca [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Rate of Feed [values] => Array ( [0] => stdClass Object ( [id] => 939d9800-4053-43d0-b2b9-9554f4de3040 [attribute_id] => 86093243-873c-498f-badd-568cc3bcd9ca [value] => A-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => 0f36cd72-4381-403e-a8fa-cd68f7094e2a [value_id] => 939d9800-4053-43d0-b2b9-9554f4de3040 [subvalue] => 180°/s [subvalues2] => Array ( ) ) ) ) ) ) [7] => stdClass Object ( [id] => d07ecf2c-eb9d-40e2-b9ba-71e13d1b80fb [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Acceleration [values] => Array ( [0] => stdClass Object ( [id] => 45968c39-f1d1-4f66-989a-15bd438e2a95 [attribute_id] => d07ecf2c-eb9d-40e2-b9ba-71e13d1b80fb [value] => A-, B-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => ecada52f-2bde-4392-9073-674ea1a0517e [value_id] => 45968c39-f1d1-4f66-989a-15bd438e2a95 [subvalue] => 700°/s2 [subvalues2] => Array ( ) ) ) ) ) ) [8] => stdClass Object ( [id] => 5b6a25e6-61a1-48c5-9cd2-7450b4ea4da1 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Resolution [values] => Array ( [0] => stdClass Object ( [id] => e8325509-c4f6-465d-a353-34624715e632 [attribute_id] => 5b6a25e6-61a1-48c5-9cd2-7450b4ea4da1 [value] => A-, B-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => 635c24c6-ee13-437f-839b-79ba02c63d27 [value_id] => e8325509-c4f6-465d-a353-34624715e632 [subvalue] => 0,0001° [subvalues2] => Array ( ) ) ) ) ) ) [9] => stdClass Object ( [id] => df115a6d-326a-4dad-9058-c5ab40eb2435 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Accuracy [values] => Array ( [0] => stdClass Object ( [id] => 3a99cd71-5f02-4460-9f07-8a7f22be427c [attribute_id] => df115a6d-326a-4dad-9058-c5ab40eb2435 [value] => [subvalues] => Array ( ) ) ) ) [10] => stdClass Object ( [id] => ac18419f-2413-47c3-810c-ded63bd00b90 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Positioning Accuracy [values] => Array ( [0] => stdClass Object ( [id] => ba8ce046-94d6-4360-a95d-9140c42c3164 [attribute_id] => ac18419f-2413-47c3-810c-ded63bd00b90 [value] => A-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => a0801ef4-d2d5-41e5-909e-27bae82730b0 [value_id] => ba8ce046-94d6-4360-a95d-9140c42c3164 [subvalue] => 10" [subvalues2] => Array ( ) ) ) ) ) ) [11] => stdClass Object ( [id] => 29ea0778-dfc2-46af-850a-d2e455121910 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Repeatability [values] => Array ( [0] => stdClass Object ( [id] => dfeec494-a25b-4d32-bd87-ea10ed94f259 [attribute_id] => 29ea0778-dfc2-46af-850a-d2e455121910 [value] => A-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => a5c1b874-5968-4381-ba7f-d302d05864b1 [value_id] => dfeec494-a25b-4d32-bd87-ea10ed94f259 [subvalue] => 6" [subvalues2] => Array ( ) ) ) ) ) ) [12] => stdClass Object ( [id] => 2e3959c8-8171-4a4c-b0f2-bc74ad37154e [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Milling Spindle 74 kW (99 hp) [values] => Array ( [0] => stdClass Object ( [id] => 66d7360b-f208-48f5-8ee1-a9ccf3ca2971 [attribute_id] => 2e3959c8-8171-4a4c-b0f2-bc74ad37154e [value] => [subvalues] => Array ( ) ) ) ) [13] => stdClass Object ( [id] => 2aaa1ef5-743f-492f-8be4-6e760149cc8f [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Spindle Power [values] => Array ( [0] => stdClass Object ( [id] => 163c08fa-24b9-4e93-821f-536f725a8b9d [attribute_id] => 2aaa1ef5-743f-492f-8be4-6e760149cc8f [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 961a304f-a26d-40ad-9b23-a81b491f892d [value_id] => 163c08fa-24b9-4e93-821f-536f725a8b9d [subvalue] => 74 kW (99 hp) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 37ab3c9a-2176-49ac-9eb6-fa00fa975e1d [attribute_id] => 2aaa1ef5-743f-492f-8be4-6e760149cc8f [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => b51f8f2b-c5e0-4d50-a7a6-8c6ff89155b1 [value_id] => 37ab3c9a-2176-49ac-9eb6-fa00fa975e1d [subvalue] => 78 kW (105 hp) [subvalues2] => Array ( ) ) ) ) ) ) [14] => stdClass Object ( [id] => 4c3a3277-dfcc-42df-bbb0-47d4cf34a067 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Spindle Speed [values] => Array ( [0] => stdClass Object ( [id] => a69ab7ca-4414-4bd3-a713-e68fb788c852 [attribute_id] => 4c3a3277-dfcc-42df-bbb0-47d4cf34a067 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 6f806e3f-79db-4b8e-a75f-68a8f2722faf [value_id] => a69ab7ca-4414-4bd3-a713-e68fb788c852 [subvalue] => 30.000 rpm [subvalues2] => Array ( ) ) ) ) ) ) [15] => stdClass Object ( [id] => d943f53f-94f5-4ed9-a3d7-3ffa16dfd4fe [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Torque [values] => Array ( [0] => stdClass Object ( [id] => d05e6d51-b302-409a-9e75-efea0d95c346 [attribute_id] => d943f53f-94f5-4ed9-a3d7-3ffa16dfd4fe [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 52d530b1-f13f-4e65-a634-0630dfdfc259 [value_id] => d05e6d51-b302-409a-9e75-efea0d95c346 [subvalue] => 73 Nm (54 ft lb) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 2afbdf83-f2be-4ced-83f9-535ed7d107e0 [attribute_id] => d943f53f-94f5-4ed9-a3d7-3ffa16dfd4fe [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => 50daa92a-7cd0-48f5-b169-4e55b1f4a52b [value_id] => 2afbdf83-f2be-4ced-83f9-535ed7d107e0 [subvalue] => 92 Nm (68 ft lb) [subvalues2] => Array ( ) ) ) ) ) ) [16] => stdClass Object ( [id] => 2eed0e77-8314-4ed5-a650-0c09bac23364 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Tool Holder [values] => Array ( [0] => stdClass Object ( [id] => 49b193d8-60eb-4ea8-8aee-246eca822531 [attribute_id] => 2eed0e77-8314-4ed5-a650-0c09bac23364 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 3a9d47ae-ef31-4ece-9b9c-aa155d937fb4 [value_id] => 49b193d8-60eb-4ea8-8aee-246eca822531 [subvalue] => HSK-A63 [subvalues2] => Array ( ) ) ) ) ) ) [17] => stdClass Object ( [id] => 8a8718da-99fc-4920-86d6-f9c8d673edc3 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Frässpindel 125 kW (168 hp) [values] => Array ( [0] => stdClass Object ( [id] => cecee0f1-5340-4222-9933-d312bd751464 [attribute_id] => 8a8718da-99fc-4920-86d6-f9c8d673edc3 [value] => [subvalues] => Array ( ) ) ) ) [18] => stdClass Object ( [id] => ba186087-480d-4024-8c58-ed691d4d4213 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Spindle Power [values] => Array ( [0] => stdClass Object ( [id] => 704c83ba-b42d-47a0-840a-9373eb1d079b [attribute_id] => ba186087-480d-4024-8c58-ed691d4d4213 [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 74f1e0e8-0ea4-4d3b-9a71-827d51d6507f [value_id] => 704c83ba-b42d-47a0-840a-9373eb1d079b [subvalue] => 125 kW (168 hp) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 5ab1998d-b25a-4797-96d0-5cbfa674fb3b [attribute_id] => ba186087-480d-4024-8c58-ed691d4d4213 [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => bdec94c4-9422-4940-a2dd-7c7ff4d8cd62 [value_id] => 5ab1998d-b25a-4797-96d0-5cbfa674fb3b [subvalue] => 156 kW (209 hp) [subvalues2] => Array ( ) ) ) ) ) ) [19] => stdClass Object ( [id] => 43414762-fecd-4b21-b7b5-5812e7ebc566 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Spindle Speed [values] => Array ( [0] => stdClass Object ( [id] => 5093fdb0-4cb4-41c9-adc9-7f10b491e464 [attribute_id] => 43414762-fecd-4b21-b7b5-5812e7ebc566 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 9aa56810-dc3e-4dac-aaf6-2c5ff82707ce [value_id] => 5093fdb0-4cb4-41c9-adc9-7f10b491e464 [subvalue] => 30.000 rpm [subvalues2] => Array ( ) ) ) ) ) ) [20] => stdClass Object ( [id] => 32acf2ca-fb63-43d6-b8b1-d01d36febfa2 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Torque [values] => Array ( [0] => stdClass Object ( [id] => 2ee11662-fb41-4240-9d80-2ebc2d621ad2 [attribute_id] => 32acf2ca-fb63-43d6-b8b1-d01d36febfa2 [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 504f226a-e6ea-40bb-b4d2-362d28d109ac [value_id] => 2ee11662-fb41-4240-9d80-2ebc2d621ad2 [subvalue] => 60 Nm (44 ft lb) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 32a61b30-c8f0-4e4e-be82-f2dba19de31f [attribute_id] => 32acf2ca-fb63-43d6-b8b1-d01d36febfa2 [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => aba767bc-60b1-4b7f-8ddf-e215a6f09686 [value_id] => 32a61b30-c8f0-4e4e-be82-f2dba19de31f [subvalue] => 75 Nm (55 ft lb) [subvalues2] => Array ( ) ) ) ) ) ) [21] => stdClass Object ( [id] => 44cc523c-25a4-44f8-97f7-b7ec12370f04 [category_id] => f6ce37d2-5198-497d-9792-2101547b2cb7 [attribute] => Tool Holder [values] => Array ( [0] => stdClass Object ( [id] => d64b7dbd-2d30-4d91-99c0-890645d332a7 [attribute_id] => 44cc523c-25a4-44f8-97f7-b7ec12370f04 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 1f83a91e-b1a6-40c5-98b0-e017a1b48102 [value_id] => d64b7dbd-2d30-4d91-99c0-890645d332a7 [subvalue] => HSK-A63/80 [subvalues2] => Array ( ) ) ) ) ) ) ) )FZP42 & FZU42

| Milling Head | ||

| Torque Rotary Axes | in control | A-Axis: 1.200 Nm (885 ft lb) |

| C-Axis: 1.047 Nm (772 ft lb) | ||

| clamped | A-, C-Axis: 3.000 Nm (2212 ft lb) | |

| Swiveling Range | ||

| A-Axis | ± 110° oder +125/-95° | |

| C-Axis | Z-Axis < 1.500 mm (59") | 300° |

| Z-Axis ≥ 1.500 mm (59") | 360° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 180°/s |

| Acceleration | A-, B-, C-Axis | 700°/s2 |

| Resolution | A-, B-, C-Axis | 0,0001° |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 10" |

| Repeatability | A-, C-Axis | 6" |

| Milling Spindle 74 kW (99 hp) | ||

| Spindle Power | S1 (100%) | 74 kW (99 hp) |

| S6 (40%/2min) | 78 kW (105 hp) | |

| Spindle Speed | 30.000 rpm | |

| Torque | S1 (100%) | 73 Nm (54 ft lb) |

| S6 (40%/2min) | 92 Nm (68 ft lb) | |

| Tool Holder | HSK-A63 | |

| Frässpindel 125 kW (168 hp) | ||

| Spindle Power | S1 (100%) | 125 kW (168 hp) |

| S6 (40%/2min) | 156 kW (209 hp) | |

| Spindle Speed | 30.000 rpm | |

| Torque | S1 (100%) | 60 Nm (44 ft lb) |

| S6 (40%/2min) | 75 Nm (55 ft lb) | |

| Tool Holder | HSK-A63/80 |

FZH

| Milling Head | ||

| External Dimensions | Length x Width | 698 mm x 610 mm (27" x 24") |

| Torque Rotary Axes | in control | A-Axis: min. 825 Nm (608 ft lb) |

| B-, C- Axis: min. 1.200 Nm (885 ft lb) | ||

| clamped | A-Axis: min. 2.000 Nm (1475 ft lb) | |

| B-Axis: min. 1.700 Nm (1254 ft lb) | ||

| C-Axis: min. 3.000 Nm (2213 ft lb) | ||

| Working Ranges | ||

| A-Axis | ± 110° | |

| B-Axis | ± 14° | |

| C-Axis | ± 200° | |

| Drives Rotary Axes | ||

| Rate of Feed | A-Axis | 180°/s |

| B- und C-Axis | 120°/s | |

| Acceleration | A-, B-, C-Axis | 700°/s2 |

| Resolution | A-, B-, C-Axis | 0,0001° |

| Milling Spindle 74 kW (99 hp) | ||

| Spindle Power | S1 (100%) | 74 kW (99 hp) |

| S6 (40%/2min) | 78 kW (105 hp) | |

| Spindle Speed | 30.000 rpm | |

| Torque | S1 (100%) | 73 Nm (54 ft lb) |

| S6 (40%/2min) | 92 Nm (68 ft lb) | |

| Tool Holder | HSK-A63 | |

| Milling Spindle 125 kW (168 hp) | ||

| Spindle Power | S1 (100%) | 125 kW (168 hp) |

| S6 (40%/2min) | 156 kW (209 hp) | |

| Spindle Speed | 30.000 rpm | |

| Torque | S1 (100%) | 60 Nm (44 ft lb) |

| S6 (40%/2min) | 75 Nm (55 ft lb) | |

| Tool Holder | HSK-A63/80 |