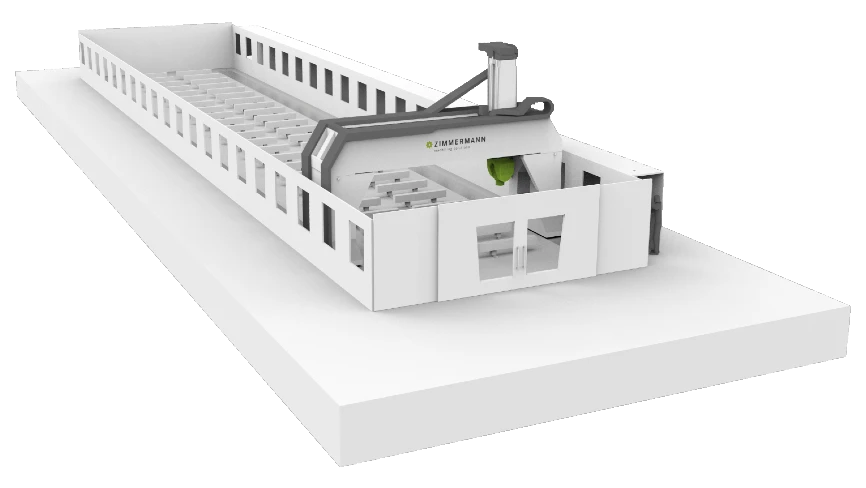

VH60

Milling Head VH60

Dynamic. Precise. Versatile.

The extremely powerful, dynamic 2-axis milling head with flexible MuST® spindle change concept masters even complex milling processes precisely. Roughing and subsequent fine machining of a wide variety of workpieces is carried out without reclamping, which significantly reduces set-up times. Various milling processes can thus be carried out with one and the same clamping.

The fork head is designed in monobloc design made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping, which ensures even more precise results during the milling process. The VH60 is designed for HSC machining of high-strength or tough materials such as steel and titanium, but also aluminium.

Technical Data

FZP42 & FZU42

| Milling Head | ||

| Torque Rotary Axes | in control | A-,C-Axis: 3.000 Nm (2212 ft lb) |

| clamped | A-Axis: 5.600 Nm (4130 ft lb) | |

| C-Axis: 6.000 Nm (4425 ft lb) | ||

| Swiveling Range | ||

| A-Axis | ± 110° oder +125/-95° | |

| C-Axis | Z-Axis < 1.500 mm (59") | 300° |

| Z-Axis ≥ 1.500 mm (59") | 360° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 360°/s |

| Acceleration | A-, B-, C-Axis | 700°/s2 |

| Resolution | A-, B-, C-Axis | 0,0001° |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 10" |

| Repeatability | A-, C-Axis | 6" |

| Milling Spindle 63 kW (84 hp) | ||

| Spindle Power | S1 (100%) | 63 kW (84 hp) |

| S6 (40%/2min) | 82 kW (110 hp) | |

| Spindle Speed | 15.000 rpm | |

| Torque | S1 (100%) | 300 Nm (221 ft lb) |

| S6 (40%/2min) | 392 Nm (289 ft lb) | |

| Tool Holder | HSK-A100 | |

| Milling Spindle 93 kW (125 hp) | ||

| Spindle Power | S1 (100%) | 93 kW (125 hp) |

| S6 (40%/2min) | 103 kW (138 hp) | |

| Spindle Speed | 8.000 rpm | |

| Torque | S1 (100%) | 444 Nm (328 ft lb) |

| S6 (40%/2min) | 553 Nm (403 ft lb) | |

| Tool Holder | HSK-A100 | |

| MuST ® Spindelwechsel-System: | ||

| 44/42 kW (59/56 hp) | 200/230 Nm (148/170 ft lb), 10 000 rpm | HSK-A100 |

| 45/60 kW (60/80 hp) | 344/454 Nm (254/335 ft lb), 5 000 rpm | HSK-A100 |

| 50/58 kW (67/78 hp) | 95/117 Nm (70/86 ft lb), 24 000 rpm | HSK-A63 |

Suitable machines