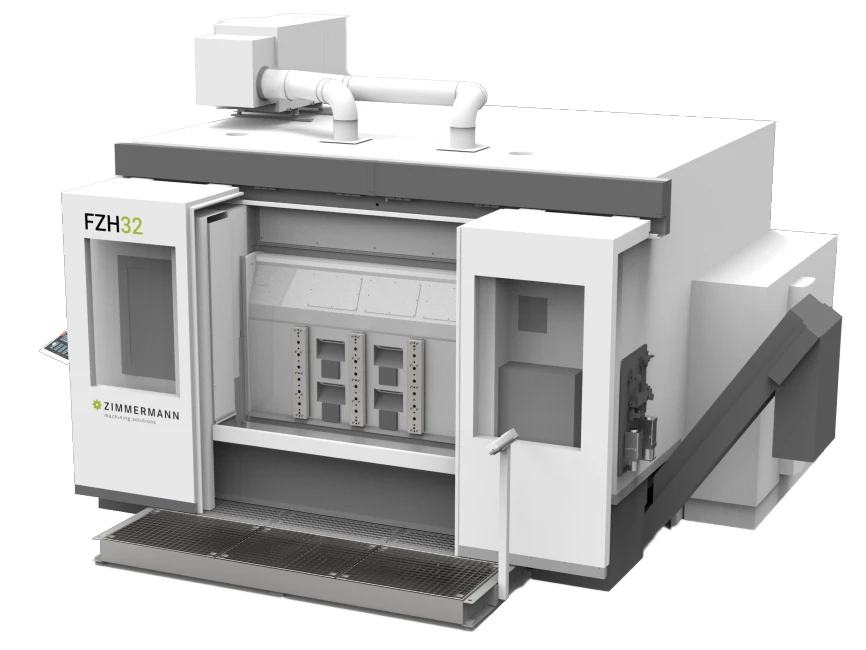

Horizontal machining centers

Thanks to their maximum metal removal rate, the horizontal machining centers are particularly suitable for machining large structural parts. In addition to their innovative moving column concept, they score points for their high precision and numerous options, which make them so individual and powerful at the same time.

Discover our machines!