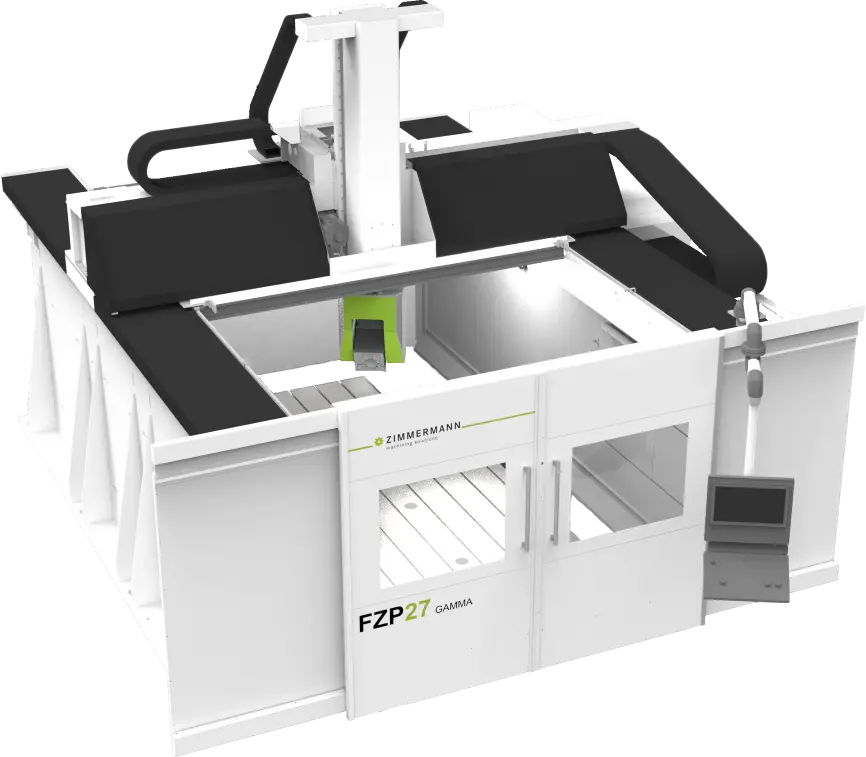

FZP27

FZP27

Customized and you

Robust. Precise. Versatile.

Machining center for large volume components mainly in aluminum or ureol. Robust construction, top travelling gantry, precise material processing. The sophisticated, well-engineered modular system ensures optimum adaptation to every machining case and every workpiece size. The spectrum of applications ranges from 1:1 models in automobile design to aircraft parts and boat hulls to parts for wagon construction.

Technical Data

Working Ranges

| X-Axis | 3 000 – 20 000 mm (118" - 787") |

| Y-Axis | 2 500/3 000/3 500 mm (98"/118"/138") |

| Z-Axis | 1 500/1 750/2 000 mm (59"/69"/78") |

Table size

| Length | 3 000 – 20 000 mm (118" - 787") |

| Width | 2 500/3 000/3 500 mm (98"/118"/138")2 |

| Height | 250 mm (10") |

| Table load | 3 000 kg/m² (max. 20 t) |

| T-Slots (longitudinal) | 18H12 |

| Pitch of T-Slots | 200 mm (8") |

Drives Linear Axes

| Feed rate X-, Y-Axis | up to 60 m/min (2362 ipm) |

| Feed rate Z-Axis | up to 40 m/min (1574 ipm) |

| Acceleration X-, Y-, Z-Axis | max. 3 – 5 m/s² (118-197 in/s²) |

Dimensions

| Required space (without peripherals) | Length | 5 380 – 22 380 mm (211"-881") |

| Width | 5 450 – 6 460 mm (214"-254") | |

| Height | 4 360 – 6 260 mm (172"-246") |

Accuracy

| Standard | in accordance to VDI/DGQ 3441 or ISO 230-2 |

Suitable milling heads

Contact us!

Available

Stock Machines

Our stock and used machines are available on short notice.