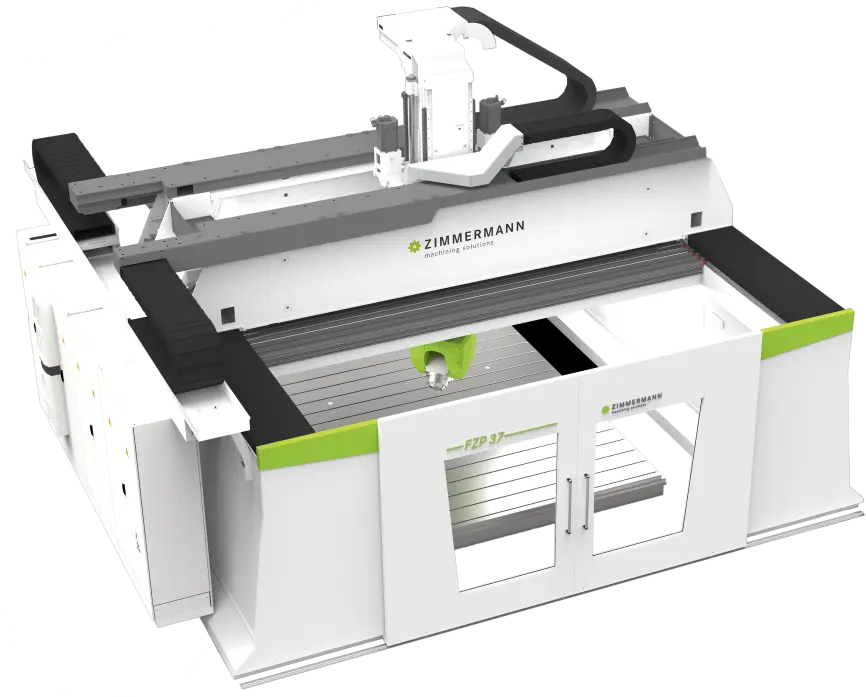

FZP37

FZP37

Performance and you

Versatile. Sophisticated. Customizable.

The FZP37 gantry milling machine has a modular design which allows different operating ranges and the use of different makes of CNC controls. The gantry construction makes it possible to machine components of all kinds. The machine table is firmly anchored to the machine base providing a stable cutting surface for material. The milling process is highly precise, regardless of weight and size.

The structurally rigid center lead portal, the cross- and Z-slides and the dynamic milling heads facilitate a consistent, efficient milling process. Thanks to their combination of high thermo-stability and rigidity the machines are able to meet all the requirements of model making, tool and mold construction, including the demands of the aerospace and automotive industries. The versatile 5/6-axis FZP37 is also suitable for machining of workpieces in shipbuilding and the alternative energy industry.

Technical Data

Working Ranges

| X-Axis | 3 000 – 40 000 mm (118"-1575") |

| Y-Axis | 2 500 – 6 000 mm (98"-236") |

| Z-Axis | 1 250 – 3 000 mm (49"-118") |

Table Size

| Length | 3 000 – 40 000 mm (118"-1575") |

| Width | 2 500 – 6 000 mm (98"-236") |

| Table load | max. 5 000 kg/m² |

| T-Slots (longitudinal) | 18H12 (opt. 18H8) |

| Pitch of T-Slots | 250 mm (9") |

| Machine table | above floor level/on floor level |

Drives - Linear Axes

| Feed rate X-, Y-, Z-Axis | up to 60 m/min (2362 ipm) |

| Acceleration X-, Y-, Z-Axis | up to 5 m/s² (197 in/s²) |

Dimensions

| Required space (without peripherals) | Length | 5 600 – 44 600 mm (220"-1756") |

| Width | 7 100 – 10 700 mm (280"-421") | |

| Height | 5 450 – 8 450 mm (215"-333") |

Accuracy

| Positioning Accuracy Linear (A/R – ISO 230-2) | Positioning Accuracy Rotational (A/R – ISO 230-2) | Volumetric Accuracy (A/R – ISO 230-2) | Thermostability (ISO 230-3) | |

| Standard Accuracy | ≤8μm | ≤4μm | ≤8'' | ≤5'' | ≤50μm | ≤30μm | dmax,240 ≤ 20μm |

| Increased Accuracy | ≤5μm | ≤3μm | ≤6'' | ≤4'' | ≤30μm | ≤20μm | dmax,240 ≤ 10μm |

| Market Competitors | 20μm | 10μm | ≤15'' | ≤10'' | 150μm | 100μm | dmax,240 ~ 80μm |

CNC control

| Heidenhain TNC 7 | Siemens SINUMERIK ONE |

Suitable milling heads

Various.

Available

Stock machines

Our stock and used machines are available on short notice