VH20

Miling Head VH20

Lean. Dynamic. Strong.

The VH20 milling head sets new standards. Developed to realize the idea of a universally applicable portal milling machine for volume cutting with different working ranges in all axes, the VH20 combines strong torques with high rotation speeds in the A and C axes up to 360°/s. In combination with above-average accuracy of the entire machine concept, this results in a high surface quality. The VH20 milling head has a symmetrical design and a compact design that tapers downwards, giving it a low interference contour.

The fork head is designed in monobloc versions made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping, which ensures even more precise results during the milling process.

Technical Data

stdClass Object ( [id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [machine_id] => 258757 [category] => VH20 milling head for FZP37 & FZU37 [attributes] => Array ( [0] => stdClass Object ( [id] => 0e70dd20-37e4-4947-8a61-2911ac46dfcf [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Torque Rotary Axes [values] => Array ( [0] => stdClass Object ( [id] => 1efc3373-0b61-44e5-89a8-1cddf9774558 [attribute_id] => 0e70dd20-37e4-4947-8a61-2911ac46dfcf [value] => in control [subvalues] => Array ( [0] => stdClass Object ( [id] => 9e71558f-51a5-4223-9f63-ab55ccd4cce9 [value_id] => 1efc3373-0b61-44e5-89a8-1cddf9774558 [subvalue] => A-Axis: 1.200 Nm (885 ft lb) [subvalues2] => Array ( ) ) [1] => stdClass Object ( [id] => 74f24f12-9fbc-49e2-a917-9f182482f291 [value_id] => 1efc3373-0b61-44e5-89a8-1cddf9774558 [subvalue] => C-Axis: 1.047 Nm (772 ft lb) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 68cd2c21-9891-4e10-931e-4de66ed0101a [attribute_id] => 0e70dd20-37e4-4947-8a61-2911ac46dfcf [value] => clamped [subvalues] => Array ( [0] => stdClass Object ( [id] => 0a7d41bf-17f9-42bc-a45f-c98b4f696ca6 [value_id] => 68cd2c21-9891-4e10-931e-4de66ed0101a [subvalue] => A-, C-Axis: 3.000 Nm (2212 ft lb) [subvalues2] => Array ( ) ) ) ) ) ) [1] => stdClass Object ( [id] => 5aa16857-5abf-4050-b08b-80fdd1c0f9e6 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Swiveling Range [values] => Array ( [0] => stdClass Object ( [id] => d04a7c27-9960-47bf-9302-8fec72584baf [attribute_id] => 5aa16857-5abf-4050-b08b-80fdd1c0f9e6 [value] => [subvalues] => Array ( ) ) ) ) [2] => stdClass Object ( [id] => ffbaa8c6-d380-4de3-b103-62fe0a9bc645 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => A-Axis [values] => Array ( [0] => stdClass Object ( [id] => 8ae248fa-b001-42eb-8cdb-bd178e4b0884 [attribute_id] => ffbaa8c6-d380-4de3-b103-62fe0a9bc645 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => b65932b6-0b28-4819-93fa-b5259d2965d0 [value_id] => 8ae248fa-b001-42eb-8cdb-bd178e4b0884 [subvalue] => ± 110° oder +125/-95° [subvalues2] => Array ( ) ) ) ) ) ) [3] => stdClass Object ( [id] => 4f6e9ed9-3b44-42b8-9fea-832c3207cdd1 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => C-Axis [values] => Array ( [0] => stdClass Object ( [id] => b996b92d-d42c-4f1c-a8fc-debb7da7d551 [attribute_id] => 4f6e9ed9-3b44-42b8-9fea-832c3207cdd1 [value] => Z-Axis < 1.500 mm (59") [subvalues] => Array ( [0] => stdClass Object ( [id] => 004300a1-3efa-4333-9fec-b3a3d2e03dfa [value_id] => b996b92d-d42c-4f1c-a8fc-debb7da7d551 [subvalue] => 300° [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 80bf7d80-18f8-4203-a443-19ca060f32a7 [attribute_id] => 4f6e9ed9-3b44-42b8-9fea-832c3207cdd1 [value] => Z-Axis ≥ 1.500 mm (59") [subvalues] => Array ( [0] => stdClass Object ( [id] => 9a23a0d8-a436-484a-839b-d2788dc63f63 [value_id] => 80bf7d80-18f8-4203-a443-19ca060f32a7 [subvalue] => 360° [subvalues2] => Array ( ) ) ) ) ) ) [4] => stdClass Object ( [id] => 02d78dfd-9a18-41e5-a073-0a2f865c88bf [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Drives - Rotary Axes [values] => Array ( [0] => stdClass Object ( [id] => 1dc77b38-8003-4d44-8675-8bd582ec80ce [attribute_id] => 02d78dfd-9a18-41e5-a073-0a2f865c88bf [value] => [subvalues] => Array ( ) ) ) ) [5] => stdClass Object ( [id] => c3fb5722-27d8-49ff-b818-e707ec03ef11 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Rate of Feed [values] => Array ( [0] => stdClass Object ( [id] => 9a4e7947-7c55-4b6b-a501-e2111c3b31fa [attribute_id] => c3fb5722-27d8-49ff-b818-e707ec03ef11 [value] => A-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => 3f15eadd-6d7c-429f-860c-3336dc2e268d [value_id] => 9a4e7947-7c55-4b6b-a501-e2111c3b31fa [subvalue] => 180°/s [subvalues2] => Array ( ) ) ) ) ) ) [6] => stdClass Object ( [id] => 91ee4bc9-45fb-4c79-ad76-1dd8de06375d [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Acceleration [values] => Array ( [0] => stdClass Object ( [id] => c8aee6e8-e549-4d0b-b333-1a898afa85f7 [attribute_id] => 91ee4bc9-45fb-4c79-ad76-1dd8de06375d [value] => A-, B, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => f8b0e52f-8c1e-4da7-bd1e-9e544cd0d5bb [value_id] => c8aee6e8-e549-4d0b-b333-1a898afa85f7 [subvalue] => 700°/s2 [subvalues2] => Array ( ) ) ) ) ) ) [7] => stdClass Object ( [id] => 48c88d6f-6de6-46c3-a881-7df57048a3a4 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Resolution [values] => Array ( [0] => stdClass Object ( [id] => 013af988-7168-42b0-bb7d-df6bec85bbff [attribute_id] => 48c88d6f-6de6-46c3-a881-7df57048a3a4 [value] => A-, B, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => 3a3a9641-987c-40a3-8996-1278d0ed3a9e [value_id] => 013af988-7168-42b0-bb7d-df6bec85bbff [subvalue] => 0,0001° [subvalues2] => Array ( ) ) ) ) ) ) [8] => stdClass Object ( [id] => 9988bf79-3f4a-489d-a91c-2acd9c0c7d8d [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Accuracy [values] => Array ( [0] => stdClass Object ( [id] => 9553d0d1-7f33-44d9-801e-779eec2ac71c [attribute_id] => 9988bf79-3f4a-489d-a91c-2acd9c0c7d8d [value] => [subvalues] => Array ( ) ) ) ) [9] => stdClass Object ( [id] => 40942bb5-d54c-476d-bca4-9cb25c873414 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Positioning Accuracy [values] => Array ( [0] => stdClass Object ( [id] => eae5e658-3412-4829-8655-bc28387b5223 [attribute_id] => 40942bb5-d54c-476d-bca4-9cb25c873414 [value] => A-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => fcf3b945-5119-4429-8013-9313b35eccd7 [value_id] => eae5e658-3412-4829-8655-bc28387b5223 [subvalue] => 10" [subvalues2] => Array ( ) ) ) ) ) ) [10] => stdClass Object ( [id] => 61e16ea6-fa19-4d05-8392-a71cb90d7c1c [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Repeatability [values] => Array ( [0] => stdClass Object ( [id] => bd16785c-4439-4409-903a-7e6401dfabc0 [attribute_id] => 61e16ea6-fa19-4d05-8392-a71cb90d7c1c [value] => A-, C-Axis [subvalues] => Array ( [0] => stdClass Object ( [id] => 12bb2628-826c-4657-a126-1e45fb84b406 [value_id] => bd16785c-4439-4409-903a-7e6401dfabc0 [subvalue] => 6" [subvalues2] => Array ( ) ) ) ) ) ) [11] => stdClass Object ( [id] => b96c3685-bd03-4c44-ae72-e86812aad05a [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Milling Spindle 39 kW (52 hp) [values] => Array ( [0] => stdClass Object ( [id] => af9763a2-8bed-45f6-b9a8-39db95790a9a [attribute_id] => b96c3685-bd03-4c44-ae72-e86812aad05a [value] => [subvalues] => Array ( ) ) ) ) [12] => stdClass Object ( [id] => 3f377dad-7be4-45b2-9a95-0b8074c21661 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Spindle Power [values] => Array ( [0] => stdClass Object ( [id] => 178622b3-7b1d-448b-9e91-d7313cb01011 [attribute_id] => 3f377dad-7be4-45b2-9a95-0b8074c21661 [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => ceb6a898-b985-484f-920e-ba59eda44c41 [value_id] => 178622b3-7b1d-448b-9e91-d7313cb01011 [subvalue] => 39 kW (52 hp) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => b149d8ab-b4fd-414c-bfc8-eb92e019f8d1 [attribute_id] => 3f377dad-7be4-45b2-9a95-0b8074c21661 [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => cab3f070-b6cc-4683-ac3c-cb7c81a7b296 [value_id] => b149d8ab-b4fd-414c-bfc8-eb92e019f8d1 [subvalue] => 52 kW (70 hp) [subvalues2] => Array ( ) ) ) ) ) ) [13] => stdClass Object ( [id] => 2898f6a8-6e05-4f58-b423-074906b93bcc [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Spindle Speed [values] => Array ( [0] => stdClass Object ( [id] => 42ff0373-aa4b-4189-b2f7-9e5d8e6454de [attribute_id] => 2898f6a8-6e05-4f58-b423-074906b93bcc [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 8b79e86f-3a28-4e07-ba1b-9f396d0302d7 [value_id] => 42ff0373-aa4b-4189-b2f7-9e5d8e6454de [subvalue] => 24.000 rpm [subvalues2] => Array ( ) ) ) ) ) ) [14] => stdClass Object ( [id] => 2a16df2f-2da8-452b-ab75-eb1d928615dd [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Torque [values] => Array ( [0] => stdClass Object ( [id] => 9535a118-6091-42b9-a980-3f2479bbd17c [attribute_id] => 2a16df2f-2da8-452b-ab75-eb1d928615dd [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 65c7135b-cdbd-4fff-9996-f6d4a35409e8 [value_id] => 9535a118-6091-42b9-a980-3f2479bbd17c [subvalue] => 32 Nm (24 ft lb) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 91eddedf-4e79-40eb-ae70-5ad4c040081a [attribute_id] => 2a16df2f-2da8-452b-ab75-eb1d928615dd [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => d328a9ef-c7da-447f-b529-3e9ccc2bb95b [value_id] => 91eddedf-4e79-40eb-ae70-5ad4c040081a [subvalue] => 43 Nm (32 ft lb) [subvalues2] => Array ( ) ) ) ) ) ) [15] => stdClass Object ( [id] => 5aac10fd-4892-4a1c-922f-08a4b5be0550 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Constant Power [values] => Array ( [0] => stdClass Object ( [id] => 40c70da1-f7e7-4819-b546-1ed40bebdf70 [attribute_id] => 5aac10fd-4892-4a1c-922f-08a4b5be0550 [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 2e930e93-601c-468e-ad86-a63c736c1a35 [value_id] => 40c70da1-f7e7-4819-b546-1ed40bebdf70 [subvalue] => 11.550-24.000 rpm [subvalues2] => Array ( ) ) ) ) ) ) [16] => stdClass Object ( [id] => d5a237a4-e67f-40aa-9e82-f8ce6f299fe8 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Swivel Axis - Spindle Nose [values] => Array ( [0] => stdClass Object ( [id] => 0b69dd25-5e14-45ca-be16-7d66057c1880 [attribute_id] => d5a237a4-e67f-40aa-9e82-f8ce6f299fe8 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => a1ba4092-4e97-4a66-9e88-7caee7824770 [value_id] => 0b69dd25-5e14-45ca-be16-7d66057c1880 [subvalue] => 326 mm (13") [subvalues2] => Array ( ) ) ) ) ) ) [17] => stdClass Object ( [id] => 422bb533-efdb-4eeb-b1b8-85c642017e06 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Tool Holder [values] => Array ( [0] => stdClass Object ( [id] => 3d861d74-f856-46a5-9dd5-83b32e34068c [attribute_id] => 422bb533-efdb-4eeb-b1b8-85c642017e06 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 72899a98-1332-4f30-a3b7-7b2a0ae5281f [value_id] => 3d861d74-f856-46a5-9dd5-83b32e34068c [subvalue] => HSK-A63 [subvalues2] => Array ( ) ) ) ) ) ) [18] => stdClass Object ( [id] => 7532e988-8a68-4ae5-aed4-3fe47a8db660 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Tool Clamping [values] => Array ( [0] => stdClass Object ( [id] => 763f677e-0ca0-4d91-839b-2d3236035b3f [attribute_id] => 7532e988-8a68-4ae5-aed4-3fe47a8db660 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 6f2f3482-fcfe-4a9c-b05d-2ddb17745e2c [value_id] => 763f677e-0ca0-4d91-839b-2d3236035b3f [subvalue] => Spring Clamp [subvalues2] => Array ( ) ) ) ) ) ) [19] => stdClass Object ( [id] => a3cf944d-b5f3-4027-bf8c-705e8ad3e585 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Tool Release [values] => Array ( [0] => stdClass Object ( [id] => 9166a9ad-acab-4650-b565-85ef35278f6d [attribute_id] => a3cf944d-b5f3-4027-bf8c-705e8ad3e585 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => d21bc776-e7a0-4bc2-b0dd-b3da58f78032 [value_id] => 9166a9ad-acab-4650-b565-85ef35278f6d [subvalue] => Hydraulic [subvalues2] => Array ( ) ) ) ) ) ) [20] => stdClass Object ( [id] => b6ced36e-38ad-4d68-891f-dae268e86bad [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Coolant Supply, Air Blowing [values] => Array ( [0] => stdClass Object ( [id] => cad84a2a-563d-41a3-a983-3860560540d8 [attribute_id] => b6ced36e-38ad-4d68-891f-dae268e86bad [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => d55a1672-cef4-4be7-b431-f9659dfc1058 [value_id] => cad84a2a-563d-41a3-a983-3860560540d8 [subvalue] => External and Through Tool [subvalues2] => Array ( ) ) ) ) ) ) [21] => stdClass Object ( [id] => 99097600-e7ab-467c-8d3b-436aacb32430 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Milling Spindle 42 kW (56 hp) [values] => Array ( [0] => stdClass Object ( [id] => 8e492842-3699-47fb-8ce0-f30eb5fb652a [attribute_id] => 99097600-e7ab-467c-8d3b-436aacb32430 [value] => [subvalues] => Array ( ) ) ) ) [22] => stdClass Object ( [id] => cf3b5c57-6d50-4695-907e-f3f9755442cf [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Spindle Power [values] => Array ( [0] => stdClass Object ( [id] => 2f666a3b-603f-4f59-8297-2eee89378d7f [attribute_id] => cf3b5c57-6d50-4695-907e-f3f9755442cf [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => 5c471f70-b96d-4507-a094-8568904dc8c6 [value_id] => 2f666a3b-603f-4f59-8297-2eee89378d7f [subvalue] => 42 kW (56 hp) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => cdc7f747-b56b-4b72-990f-97e01d28a8d1 [attribute_id] => cf3b5c57-6d50-4695-907e-f3f9755442cf [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => fe9da8b3-27f2-468e-927c-8442736d70e4 [value_id] => cdc7f747-b56b-4b72-990f-97e01d28a8d1 [subvalue] => 48 kW (64 hp) [subvalues2] => Array ( ) ) ) ) ) ) [23] => stdClass Object ( [id] => 5ba259e0-f07b-45b5-9e9b-9ccccf65aa83 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Spindle Speed [values] => Array ( [0] => stdClass Object ( [id] => cf45debc-91ab-479a-be6a-2d8a3147f76e [attribute_id] => 5ba259e0-f07b-45b5-9e9b-9ccccf65aa83 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 77c7c4c5-f2fd-4a19-9511-619fdc0695a4 [value_id] => cf45debc-91ab-479a-be6a-2d8a3147f76e [subvalue] => 24.000 rpm [subvalues2] => Array ( ) ) ) ) ) ) [24] => stdClass Object ( [id] => 17b900cb-aa14-4a8f-900f-b88bfdd29599 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Torque [values] => Array ( [0] => stdClass Object ( [id] => b14cd42c-b585-40d8-9c3a-2bf39bc85fe5 [attribute_id] => 17b900cb-aa14-4a8f-900f-b88bfdd29599 [value] => S1 (100%) [subvalues] => Array ( [0] => stdClass Object ( [id] => d80fc0f4-e9ac-431c-8681-748533f893a2 [value_id] => b14cd42c-b585-40d8-9c3a-2bf39bc85fe5 [subvalue] => 67 Nm (49 ft lb) [subvalues2] => Array ( ) ) ) ) [1] => stdClass Object ( [id] => 24cc6c31-3b30-452e-94a1-797ce666dc72 [attribute_id] => 17b900cb-aa14-4a8f-900f-b88bfdd29599 [value] => S6 (40%/2min) [subvalues] => Array ( [0] => stdClass Object ( [id] => 8e1259b0-8783-4ec4-b76d-44c68687b464 [value_id] => 24cc6c31-3b30-452e-94a1-797ce666dc72 [subvalue] => 76 Nm (56 ft lb) [subvalues2] => Array ( ) ) ) ) ) ) [25] => stdClass Object ( [id] => 911260bf-f739-490d-a90a-412a9cd0454f [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Constant Power [values] => Array ( [0] => stdClass Object ( [id] => 86e0e9b5-9b27-497e-9b08-1783b6859c93 [attribute_id] => 911260bf-f739-490d-a90a-412a9cd0454f [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => ab6dcbeb-4b42-4909-95e8-2c594d21e45f [value_id] => 86e0e9b5-9b27-497e-9b08-1783b6859c93 [subvalue] => 6.000-24.000 rpm [subvalues2] => Array ( ) ) ) ) ) ) [26] => stdClass Object ( [id] => d8e718f7-c645-40b3-a85e-89f981f19885 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Swivel Axis - Spindle Nose [values] => Array ( [0] => stdClass Object ( [id] => bbc1ce21-9fe5-48d6-a7af-32fd838e9f16 [attribute_id] => d8e718f7-c645-40b3-a85e-89f981f19885 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => e7eec5ed-bcc0-481c-b3d1-ece019732633 [value_id] => bbc1ce21-9fe5-48d6-a7af-32fd838e9f16 [subvalue] => 326 mm [subvalues2] => Array ( ) ) ) ) ) ) [27] => stdClass Object ( [id] => 626d2309-7c3f-4ee7-afb9-c8c5f6148af9 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Tool Holder [values] => Array ( [0] => stdClass Object ( [id] => 686582c8-d4fd-41b6-8989-f8bbb5075241 [attribute_id] => 626d2309-7c3f-4ee7-afb9-c8c5f6148af9 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => f753d004-cf21-4f3c-b7e6-9f7683d10c53 [value_id] => 686582c8-d4fd-41b6-8989-f8bbb5075241 [subvalue] => HSK-A63 [subvalues2] => Array ( ) ) ) ) ) ) [28] => stdClass Object ( [id] => 3730440b-51d7-4eca-81ad-494bc6c15538 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Tool Clamping [values] => Array ( [0] => stdClass Object ( [id] => 652be152-9722-493e-8d48-a902673834f7 [attribute_id] => 3730440b-51d7-4eca-81ad-494bc6c15538 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => bbd3748d-8de9-485a-b157-d4d7ab7fcac1 [value_id] => 652be152-9722-493e-8d48-a902673834f7 [subvalue] => Spring Clamp [subvalues2] => Array ( ) ) ) ) ) ) [29] => stdClass Object ( [id] => b0f5fb18-ca7e-4a90-9aff-e770377c7c0a [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Tool Release [values] => Array ( [0] => stdClass Object ( [id] => 3ba62f4b-cd83-4b9e-a3a3-2943eb08acee [attribute_id] => b0f5fb18-ca7e-4a90-9aff-e770377c7c0a [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => 571af078-e3db-403b-ae66-363365c9a910 [value_id] => 3ba62f4b-cd83-4b9e-a3a3-2943eb08acee [subvalue] => Hydraulic [subvalues2] => Array ( ) ) ) ) ) ) [30] => stdClass Object ( [id] => 9c67c596-8b40-497a-81e9-84ad7abda029 [category_id] => 76c3d274-7e4f-4197-ba90-6b0858ec0ad4 [attribute] => Coolant Supply, Air Blowing [values] => Array ( [0] => stdClass Object ( [id] => e35546c8-98d1-419f-beab-9678634e1be1 [attribute_id] => 9c67c596-8b40-497a-81e9-84ad7abda029 [value] => [subvalues] => Array ( [0] => stdClass Object ( [id] => c3e32678-810b-4b93-9bca-147098e8a83c [value_id] => e35546c8-98d1-419f-beab-9678634e1be1 [subvalue] => External and Through Tool [subvalues2] => Array ( ) ) ) ) ) ) ) )VH20 milling head for FZP37 & FZU37

| Torque Rotary Axes | in control | A-Axis: 1.200 Nm (885 ft lb) |

| C-Axis: 1.047 Nm (772 ft lb) | ||

| clamped | A-, C-Axis: 3.000 Nm (2212 ft lb) | |

| Swiveling Range | ||

| A-Axis | ± 110° oder +125/-95° | |

| C-Axis | Z-Axis < 1.500 mm (59") | 300° |

| Z-Axis ≥ 1.500 mm (59") | 360° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 180°/s |

| Acceleration | A-, B, C-Axis | 700°/s2 |

| Resolution | A-, B, C-Axis | 0,0001° |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 10" |

| Repeatability | A-, C-Axis | 6" |

| Milling Spindle 39 kW (52 hp) | ||

| Spindle Power | S1 (100%) | 39 kW (52 hp) |

| S6 (40%/2min) | 52 kW (70 hp) | |

| Spindle Speed | 24.000 rpm | |

| Torque | S1 (100%) | 32 Nm (24 ft lb) |

| S6 (40%/2min) | 43 Nm (32 ft lb) | |

| Constant Power | S1 (100%) | 11.550-24.000 rpm |

| Swivel Axis - Spindle Nose | 326 mm (13") | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic | |

| Coolant Supply, Air Blowing | External and Through Tool | |

| Milling Spindle 42 kW (56 hp) | ||

| Spindle Power | S1 (100%) | 42 kW (56 hp) |

| S6 (40%/2min) | 48 kW (64 hp) | |

| Spindle Speed | 24.000 rpm | |

| Torque | S1 (100%) | 67 Nm (49 ft lb) |

| S6 (40%/2min) | 76 Nm (56 ft lb) | |

| Constant Power | 6.000-24.000 rpm | |

| Swivel Axis - Spindle Nose | 326 mm | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic | |

| Coolant Supply, Air Blowing | External and Through Tool |

VH20 milling head for FZP32 & FZU32

| Torque Rotary Axes | in control | A-Axis: 1.200 Nm (885 ft lb) |

| C-Axis: 1.047 Nm (772 ft lb) | ||

| clamped | A-, C-Axis: 3.000 Nm (2212 ft lb) | |

| Swiveling Range | ||

| A-Axis | ± 110° oder +125/-95° | |

| C-Axis | Z-Axis < 1.500 mm (59") | 300° |

| Z-Axis ≥ 1.500 mm (59") | 360° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 180°/s |

| Acceleration | A-, B, C-Axis | 700°/s2 |

| Resolution | A-, B, C-Axis | 0,0001° |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 10" |

| Repeatability | A-, C-Axis | 6" |

| Milling Spindle 39 kW (52 hp) | ||

| Spindle Power | S1 (100%) | 39 kW (52 hp) |

| S6 (40%/2min) | 52 kW (70 hp) | |

| Spindle Speed | 24.000 rpm | |

| Torque | S1 (100%) | 32 Nm (24 ft lb) |

| S6 (40%/2min) | 43 Nm (32 ft lb) | |

| Constant Power | S1 (100%) | 11.550-24.000 rpm |

| Swivel Axis - Spindle Nose | 326 mm (13") | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic | |

| Coolant Supply, Air Blowing | External and Through Tool | |

| Milling Spindle 42 kW (56 hp) | ||

| Spindle Power | S1 (100%) | 42 kW (56 hp) |

| S6 (40%/2min) | 48 kW (64 hp) | |

| Spindle Speed | 24.000 rpm | |

| Torque | S1 (100%) | 67 Nm (49 ft lb) |

| S6 (40%/2min) | 76 Nm (56 ft lb) | |

| Constant Power | 6.000-24.000 rpm | |

| Swivel Axis - Spindle Nose | 326 mm | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic | |

| Coolant Supply, Air Blowing | External and Through Tool |

Suitable machine

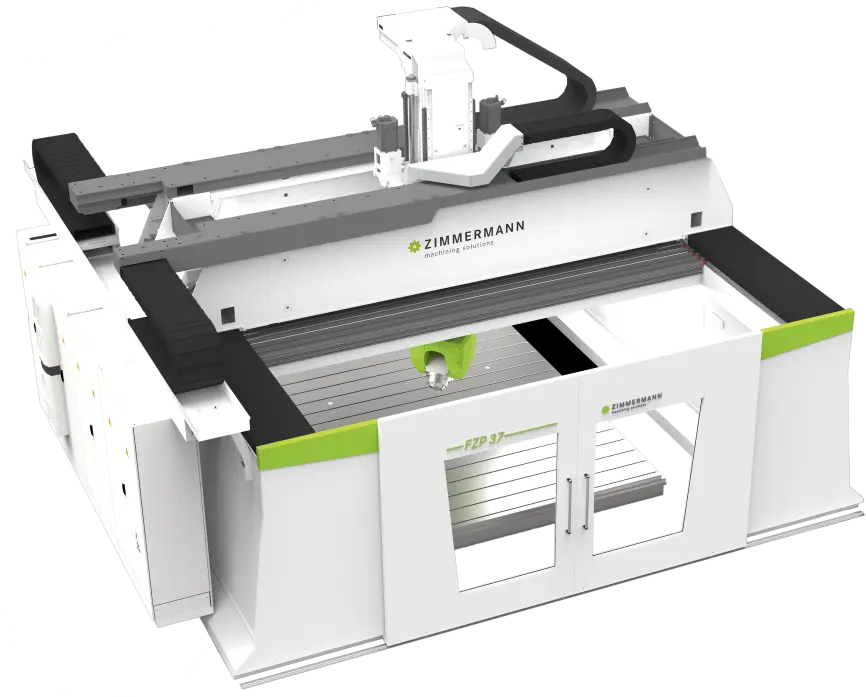

FZP37 Performance and you

Versatile. Sophisticated. Customizable.

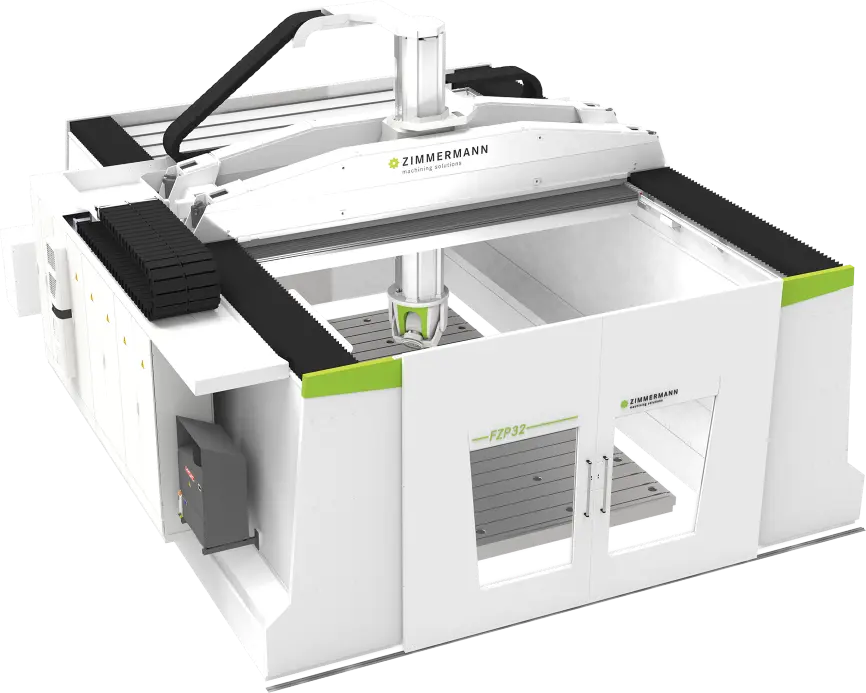

FZP32 Dynamic and you

Variable. Symmetric. Economical.

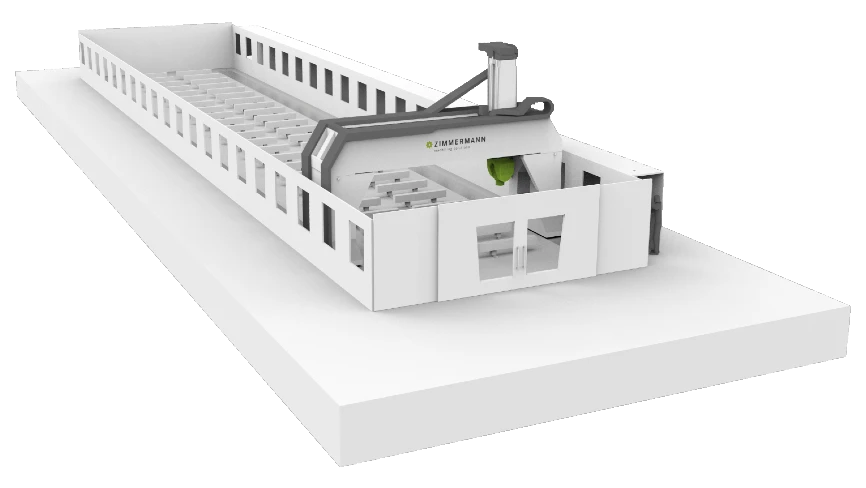

FZU37 Excellence and you

Independet. Flexible. Rigid.

FZU32 Efficiency and you

Thermosymmetrical. Ergonomic. Universal.

FZG Volume and you

5-Axis-portal milling machine - low rail gantry