Gantry Machines

Experience how close maximum mechanical accuracy comes to perfection. From the portal milling machines in classic design to the 5- and 6-axis gantry portal milling machines, all Zimmermann milling solutions ensure the highest quality and precision.

Discover our machines!

FZP42 Power and you

Strong. Agil. Versatile.

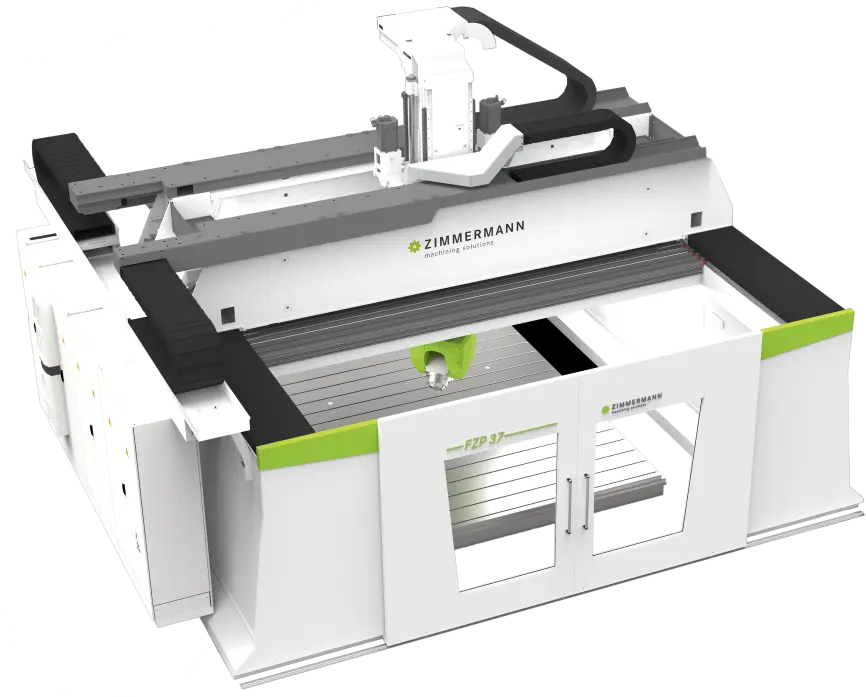

FZP37 Performance and you

Versatile. Sophisticated. Customizable.

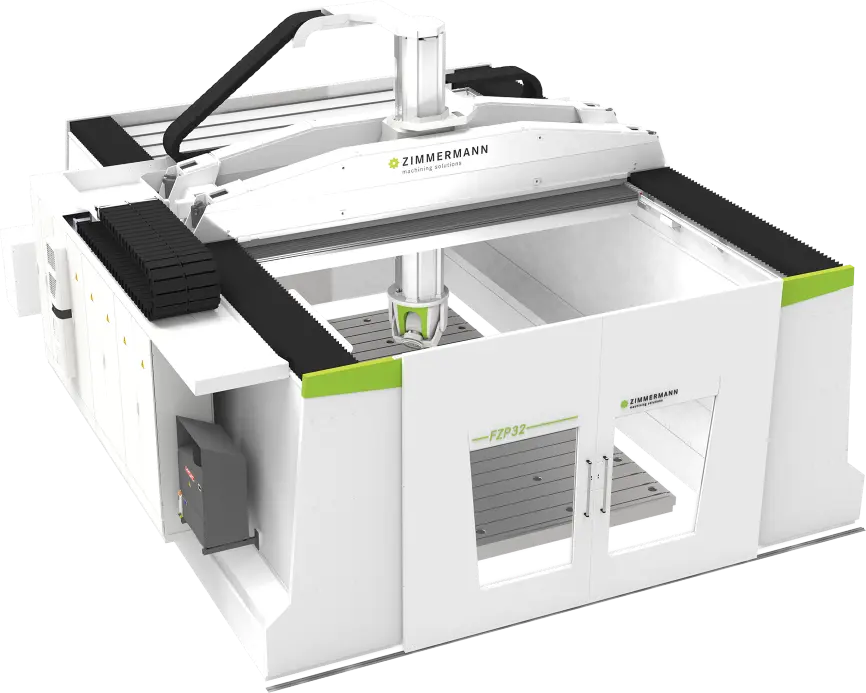

FZP32 Dynamic and you

Variable. Symmetric. Economical.

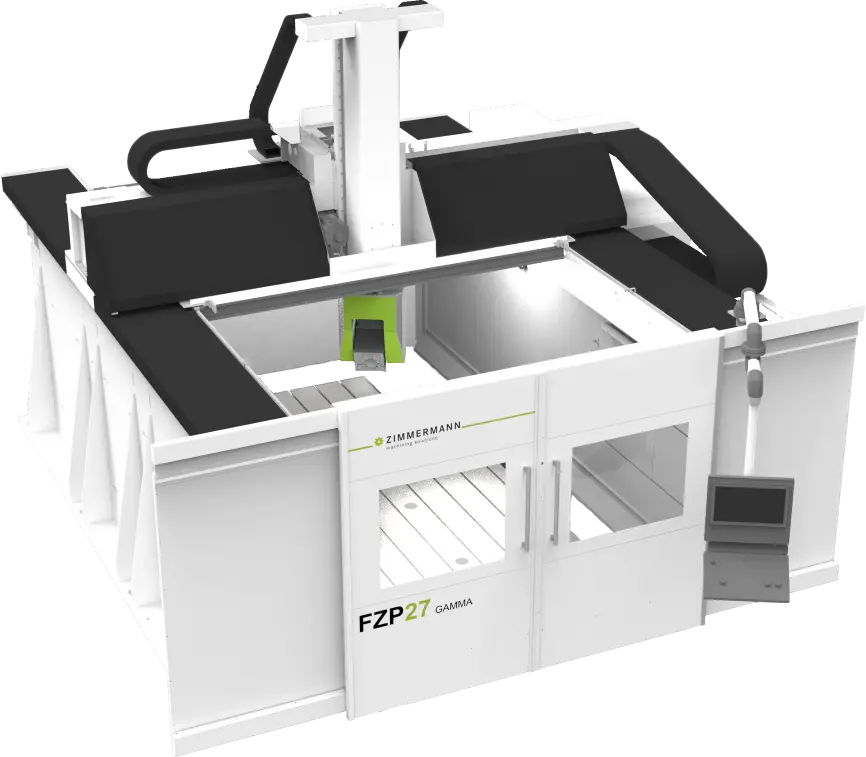

FZP27Customized and you

Robust. Precise. Versatile.

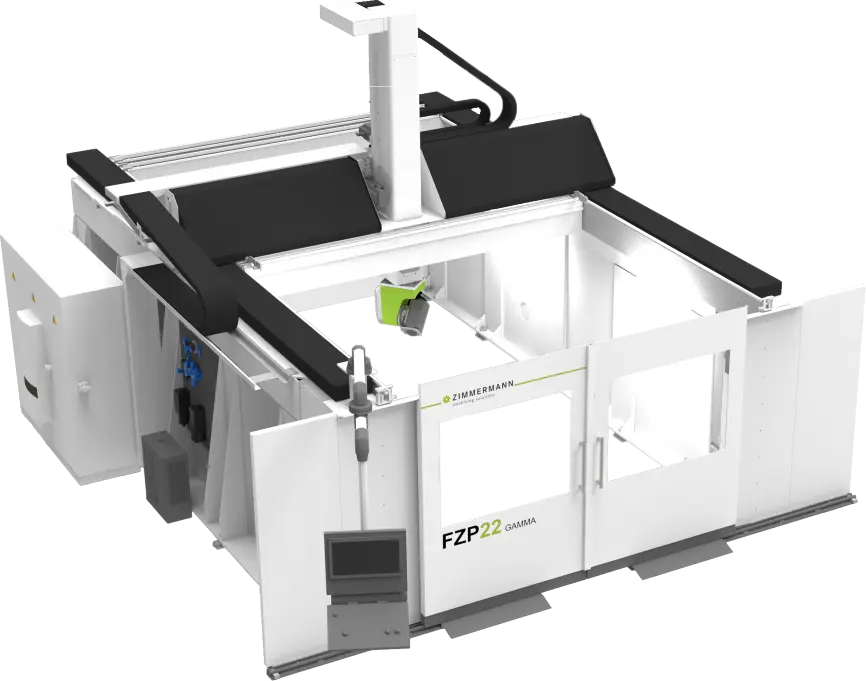

FZP22 Compact and you

Compact. Universal. Economical.

FZU42 Precision and you

Powerful Ambitious. Precise.

FZU37 Excellence and you

Independet. Flexible. Rigid.

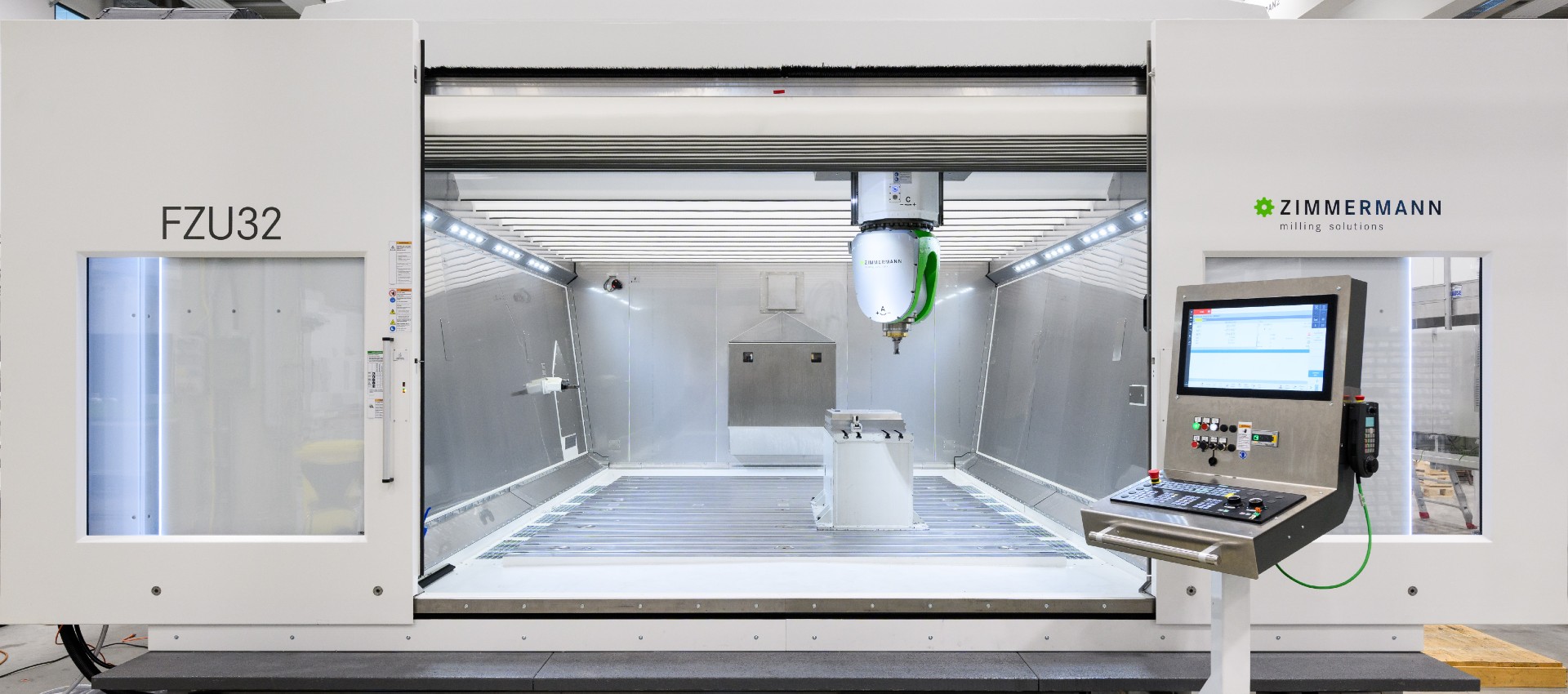

FZU32 Efficiency and you

Thermosymmetrical. Ergonomic. Universal.

FZU27 Universal and you

Robust. Dynamic. Accurate.

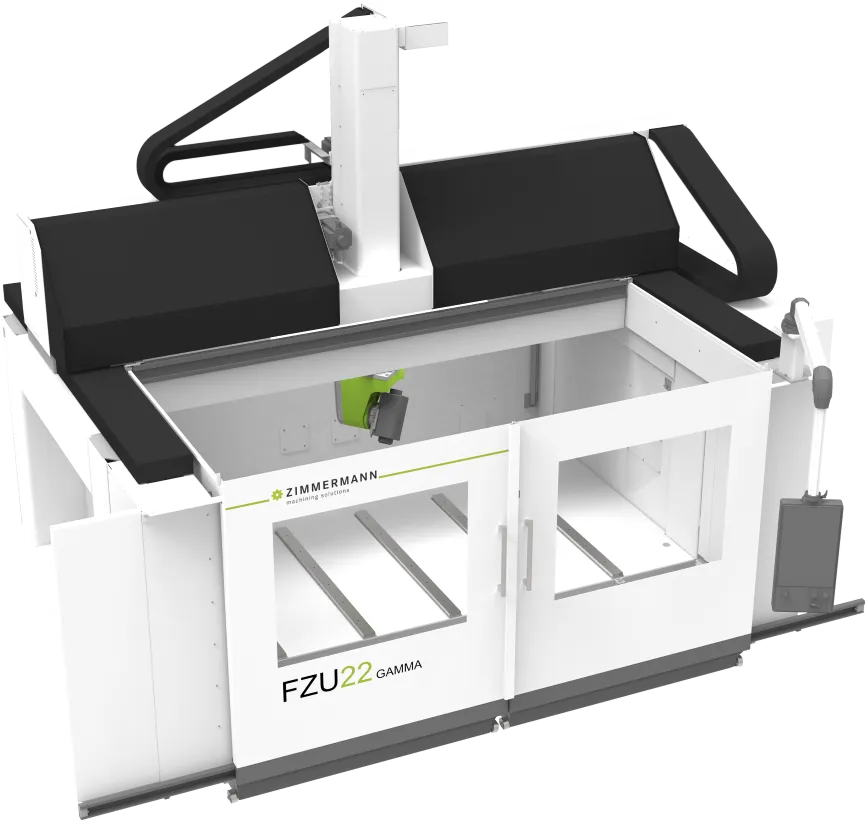

FZU22 Economical and you

Compact. Universal. Economical.

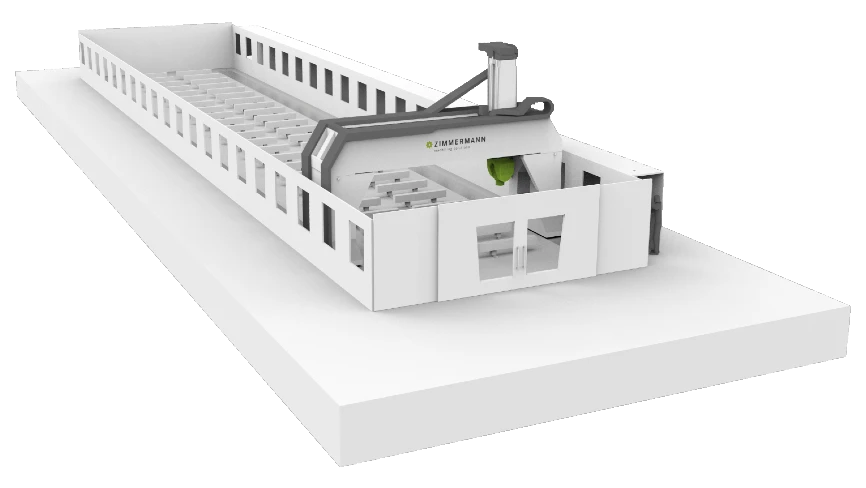

FZG Volume and you

5-Axis-portal milling machine - low rail gantry