VH10

Milling Head VH10

New. Powerful. Fast.

The newly developed dynamic 2-axis milling head VH10 has only minimal interference contours due to its slim design. The fork head is designed in monobloc versions made of cast iron. Despite its small size, the VH10 achieves high clamping forces and thus enables stable component processing. To keep throughput times short, the VH10 is available with a powerful 34 kW spindle (at 24,000 rpm).

Effective process cooling with cooling lubricants and/or minimum quantity lubrication are optionally possible. The milling head can also be used for ultrasonic cutting. The VH10 is particularly suitable for milling aluminium, composites, plastics, ureol and clay.

Technical Data

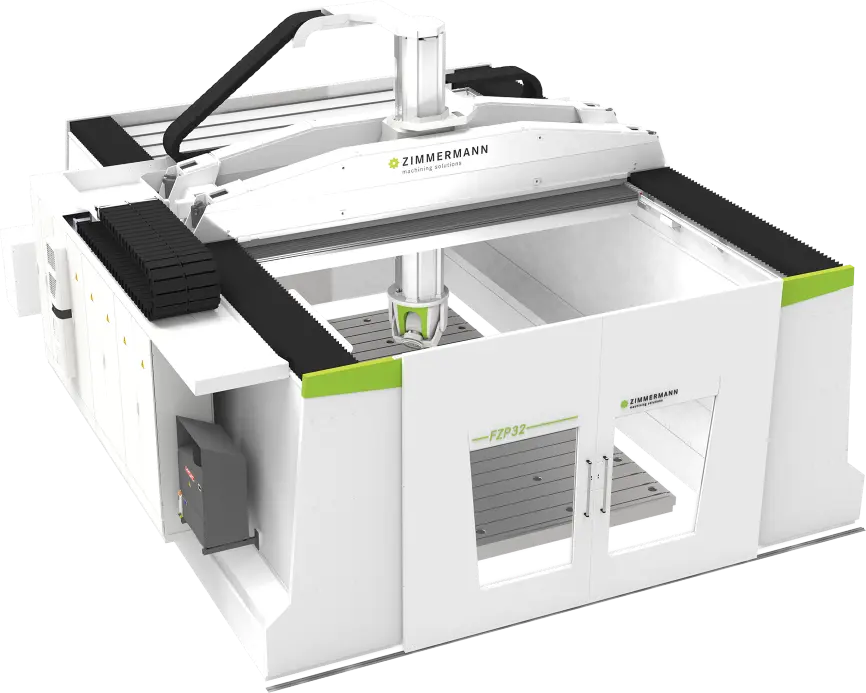

VH10 milling head for FZP32 & FZU32

| Torque Rotary Axes | in control | A-Axis: 600 Nm (442 ft lb) |

| C-Axis: 608 Nm (448 ft lb) | ||

| clamped | A-Axis: 1380 Nm (1017 ft lb) | |

| C-Axis: 1321 Nm (974 ft lb) | ||

| Swiveling Range | ||

| A-Axis | ± 110° oder +125/-95° | |

| C-Axis | 360° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 180°/s |

| Acceleration | A-, C-Axis | 700°/s2 |

| Resolution | A-, C-Axis | 0,0001° |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 12" |

| Repeatability | A-, C-Axis | 8" |

| Milling Spindle 25 kW (34 hp) | ||

| Spindle Power | S1 (100%) | 25 kW (34 hp) |

| S6 (40%/2min) | 31 kW (42 hp) | |

| Spindle Speed | 15 000 rpm | |

| Torque | S1 (100%) | 60 Nm (44 ft lb) |

| S6 (40%/2min) | 74 Nm (55 ft lb) | |

| Tool Holder | HSK-A63 | |

| Milling Spindle 34 kW (46 hp) | ||

| Spindle Power | S1 (100%) | 34 kW (46 hp) |

| S6 (40%/2min) | 41 kW (55 hp) | |

| Spindle Speed | 24 000 rpm | |

| Torque | S1 (100%) | 39 Nm (29 ft lb) |

| S6 (40%/2min) | 49 Nm (36 ft lb) | |

| Constant Power | S1 (100%) | 8 260–24 000 rpm |

| Swivel Axis - Spindle Nose | 250 mm (9") | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic |

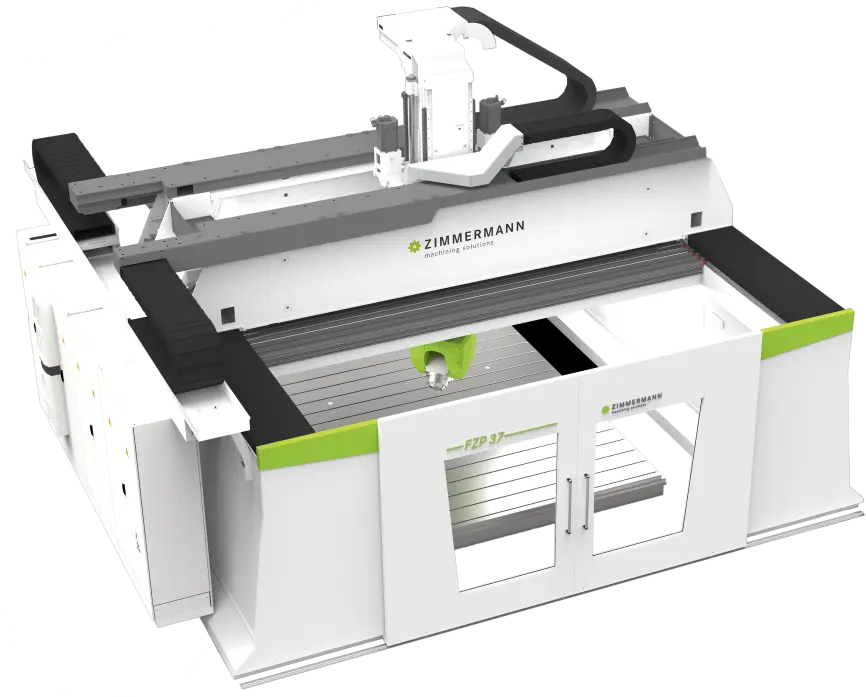

VH10 milling head for FZP37 & FZU37

| Torque Rotary Axes | in control | A-Axis: 1.200 Nm (885 ft lb) |

| C-Axis: 1.047 Nm (772 ft lb) | ||

| clamped | A-, C-Axis: 3.000 Nm (2212 ft lb) | |

| Swiveling Range | ||

| A-Axis | ± 110° oder +125/-95° | |

| C-Axis | Z-Axis < 1.500 mm (59") | 300° |

| Z-Axis ≥ 1.500 mm (59") | 360° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 180°/s |

| Acceleration | A-, B, C-Axis | 700°/s2 |

| Resolution | A-, B, C-Axis | 0,0001° |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 12" |

| Repeatability | A-, C-Axis | 8" |

| Milling Spindle 25 kW (34 hp) | ||

| Spindle Power | S1 (100%) | 25 kW (34 hp) |

| S6 (40%/2min) | 31 kW (42 hp) | |

| Spindle Speed | 15.000 rpm | |

| Torque | S1 (100%) | 60 Nm (44 ft lb) |

| S6 (40%/2min) | 49 Nm (36 ft lb) | |

| Tool Holder | HSK-A63 | |

| Milling Spindle 34 kW (46 hp) | ||

| Spindle Power | S1 (100%) | 34 kW (46 hp) |

| S6 (40%/2min) | 41 kW (55 hp) | |

| Spindle Speed | 24.000 rpm | |

| Torque | S1 (100%) | 39 Nm (29 ft lb) |

| S6 (40%/2min) | 49 Nm (36 ft lb) | |

| Constant Power | S1 (100%) | 8.260-24.000 rpm |

| Swivel Axis - Spindle Nose | 250 mm (13") | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic | |

| Coolant Supply, Air Blowing | External and Through Tool |

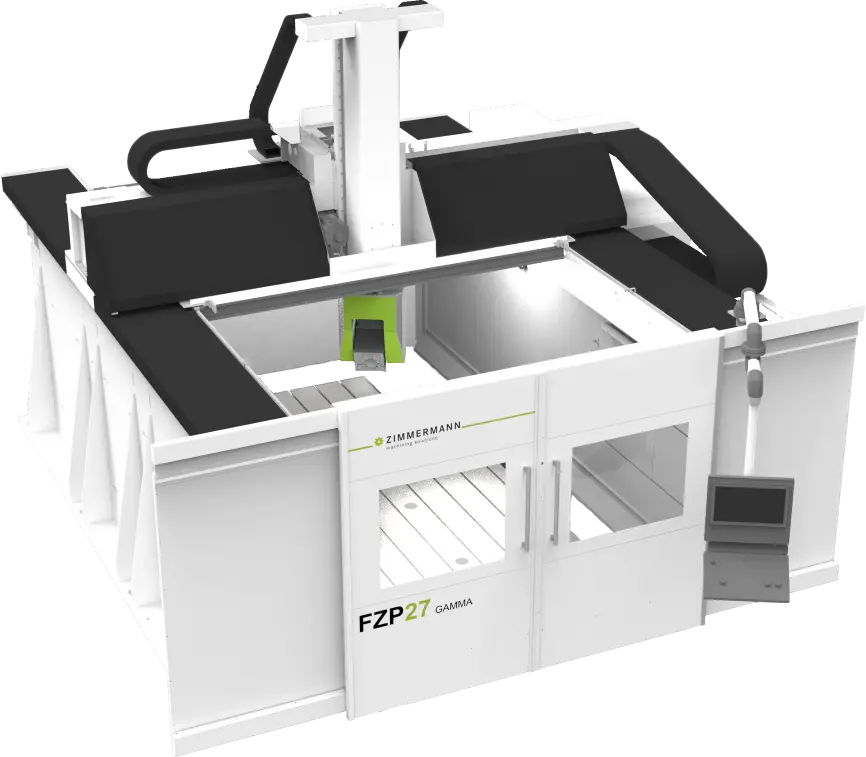

VH10 milling head for FZP27 & FZU27

| Torque Rotary Axes | in control | A-Axis: 1.180 Nm (870 ft lb), C-Axis: 1.310 Nm (966 ft lb) |

| clamped | A-, C-Axis: 1.100 Nm (811 ft lb) | |

| Swiveling Range | ||

| A-Axis | ± 96° oder ±120° | |

| C-Axis | ± 270° | |

| Drives - Rotary Axes | ||

| Rate of Feed | A-, C-Axis | 108°/s, 84°/s |

| Acceleration | A-, C-Axis | 51°/s, 31°/s |

| Accuracy | ||

| Positioning Accuracy | A-, C-Axis | 20" |

| Repeatability | A-, C-Achse | 10" |

| Milling Spindle 25 kW (34 hp) | ||

| Spindle Power | S1 (100%) | 25 kW (34 hp) |

| S6 (40%/2min) | 31 kW (42 hp) | |

| Spindle Speed | 15.000 rpm | |

| Torque | S1 (100%) | 60 Nm (44 ft lb) |

| S6 (40%/2min) | 49 Nm (36 ft lb) | |

| Tool Holder | HSK-A63 | |

| Milling Spindle 34 kW (46 hp) | ||

| Spindle Power | S1 (100%) | 34 kW (46 hp) |

| S6 (40%/2min) | 41 kW (55 hp) | |

| Spindle Speed | 24.000 rpm | |

| Torque | S1 (100%) | 39 Nm (29 ft lb) |

| S6 (40%/2min) | 49 Nm (36 ft lb) | |

| Constant Power | S1 (100%) | 8.260-24.000 rpm |

| Swivel Axis - Spindle Nose | 250 mm (13") | |

| Tool Holder | HSK-A63 | |

| Tool Clamping | Spring Clamp | |

| Tool Release | Hydraulic | |

| Coolant Supply, Air Blowing | External and Through Tool |

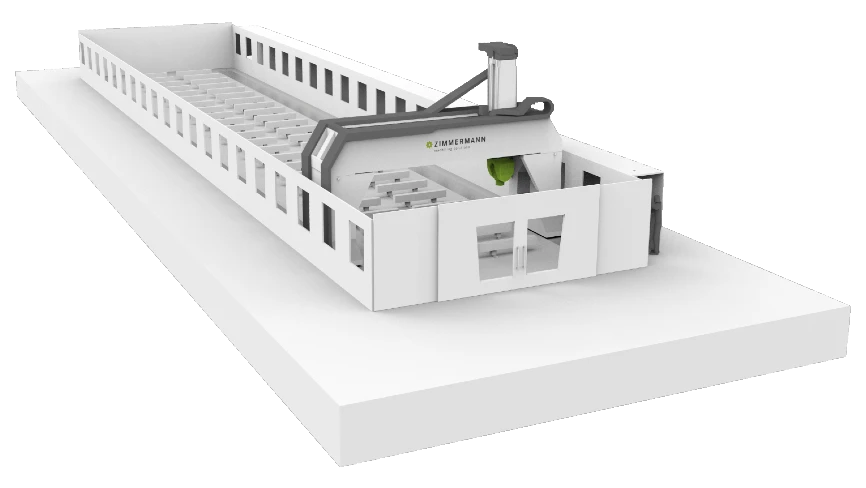

Suitable Machines