Precision and you:

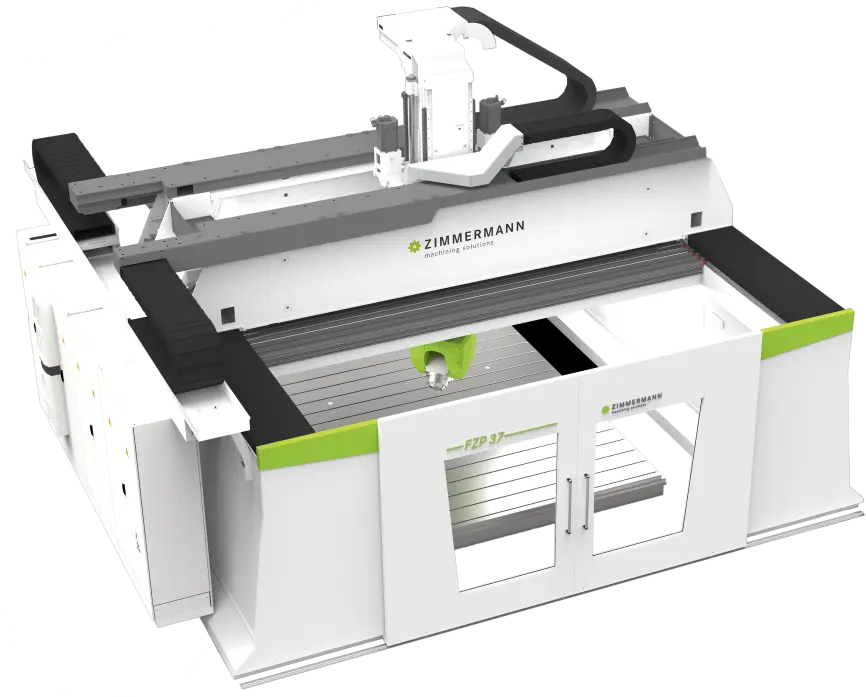

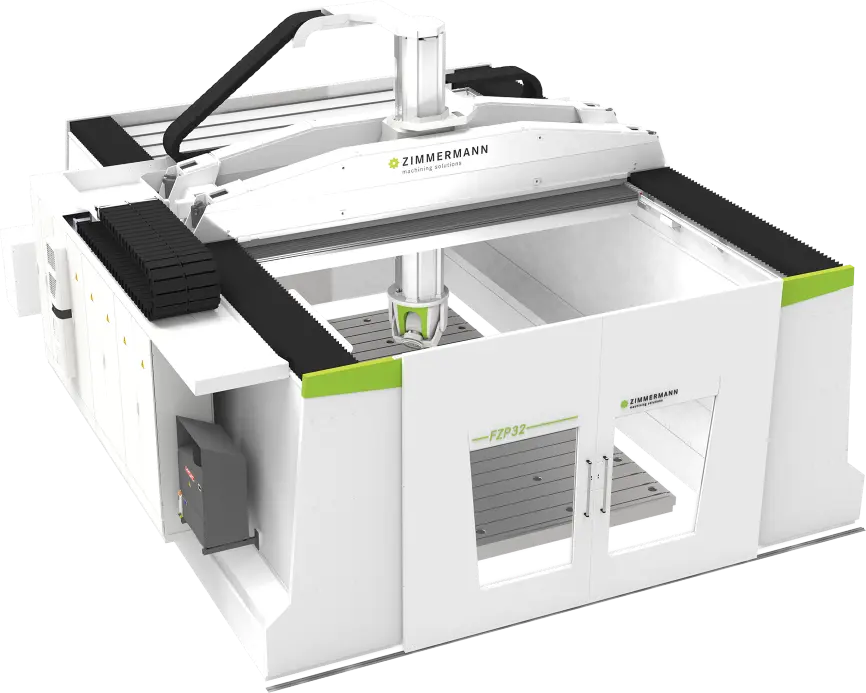

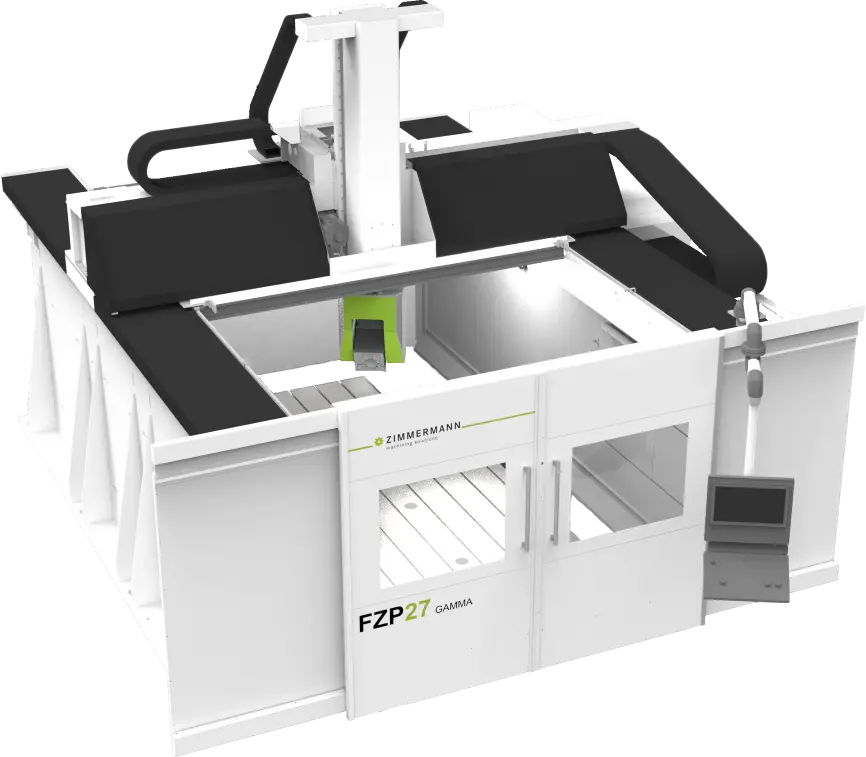

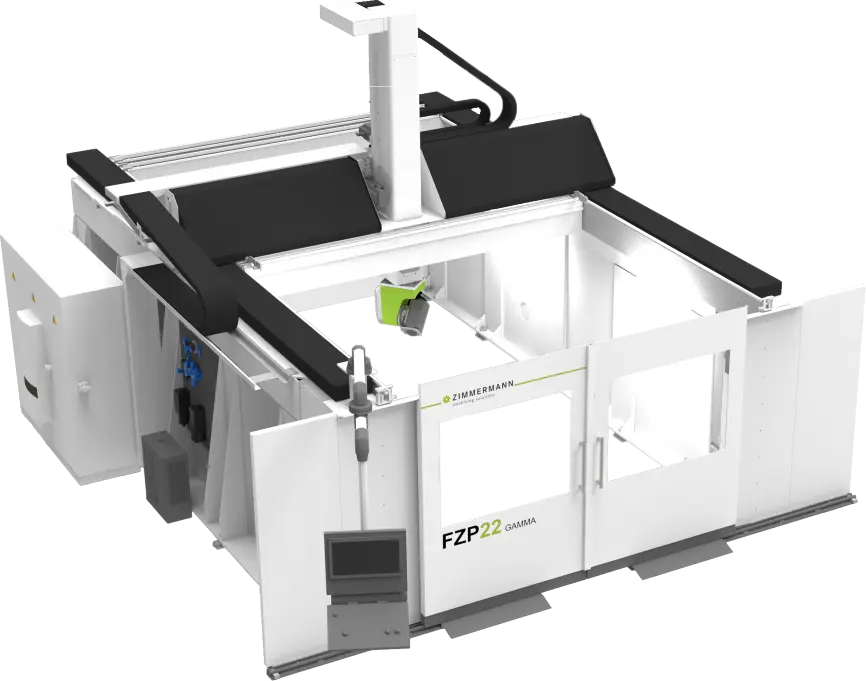

Machining solutions by Zimmermann.

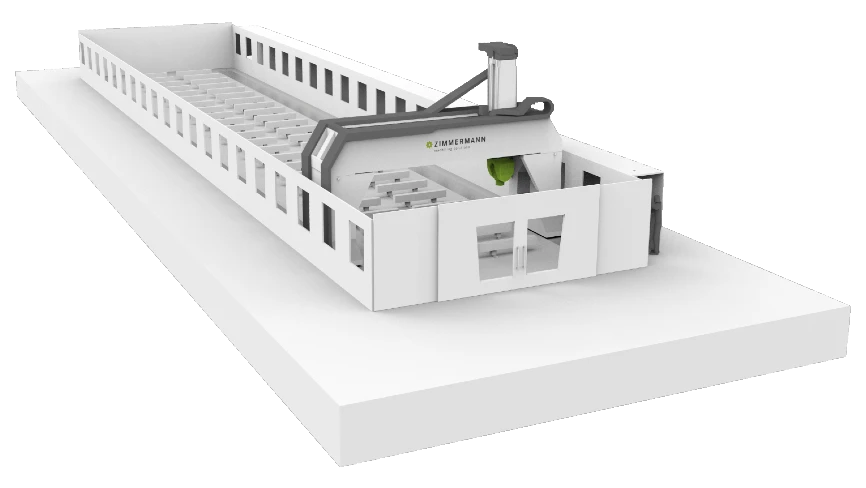

Zimmermann stands for innovative, high-quality and efficient milling solutions – worldwide. Our modular machine system provides flexibility for individuality and the innovative thermosymmetrical gantry ensures maximum accuracy. We develop your milling machine together with passion and precision. In this way, we find the right solution for every requirement, industry and for every component and material – machining solutions and you!

Milling solutions Aerospace

Milling solutions Automotive

Milling solutions Defense

Milling solutions Industry

Precise:

every μ counts.

Together:

unstoppable.

Tailored:

to your needs.

Passionate:

we live technology.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. More Information

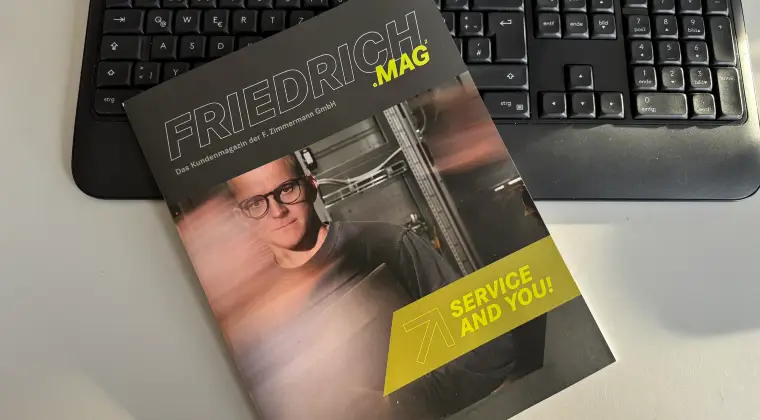

Friedrich 2025

"Friedrich" the customer magazine of F. Zimmermann: Service and you!At the heart of the new edition of our customer magazine Friedrich 2025 is our global service – and with it a clear promise to our customers: You can rely on Zimmermann. Anytime. Anywhere. Get to...

02. – 06.03.2026

BIEMH

Bilbao/ Spain

10. – 12.03.2026

JEC World

Paris/ France

10. – 13.03.2026

Technishow

Utrecht/ Netherlands

Career:

Future and you!

Detail fanatic. Precision pedant. Zero tolerance range lover. Sounds like you? Then you are right with us. We give unique character heads a home and welcome you to #Team Zimmermann.

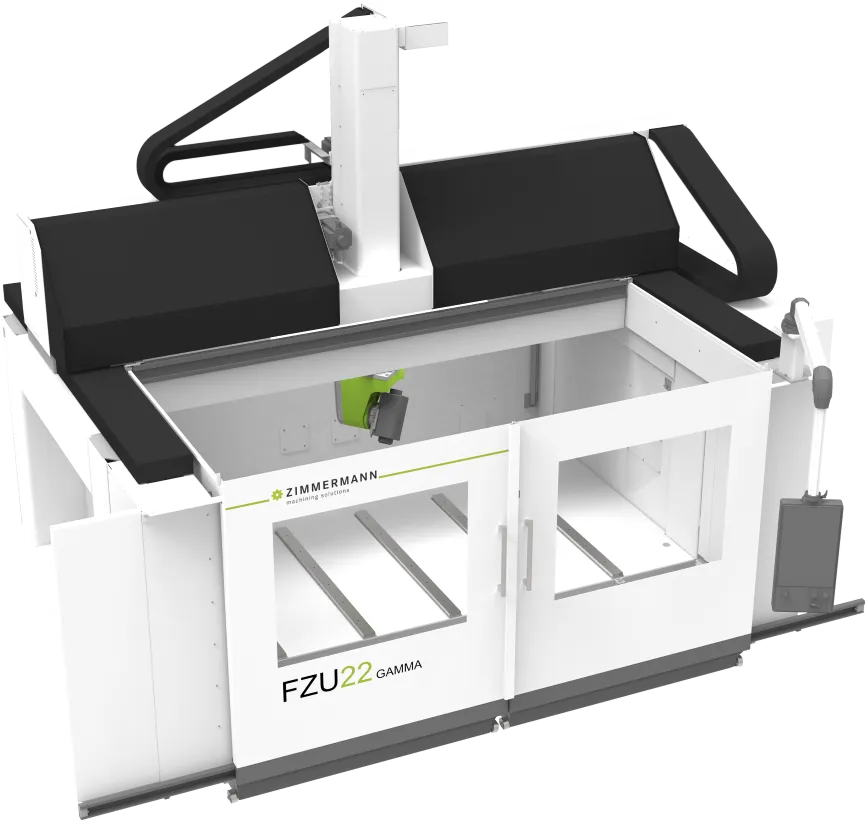

Stock machines:

Available

From our portal milling machines and horizontal machining centers we also have few in stock. They are available with short delivery time.

Service:

Working for you worldwide!

With every Zimmermann solution, we sell our customers high-performance machines. Our service team is at your side and takes care of the availability and efficiency of your machine.